Control and reduce your Manufacturing Costs with Lean

How can you increase productivity, reduce lead times, lower inventory levels, and cut manufacturing errors and defects by more than 50%? According to our Merkur experts, at least 60% of manufacturing activities in industrial companies are non–value-added actions. Here, we present a few simple principles of Lean manufacturing that can significantly improve business performance by maximizing efficiency and minimizing waste.

LEARN MORE: Lean Manufacturing

Minimize Waste and Maximize Value

Lean manufacturing aims to work with “just what is necessary”. Produce the quantity you need, when you need it, and with the required quality. Just-in-time flows, for example, contrast with traditional mass production methods, where large quantities of products are manufactured in advance and stored while waiting for future demand. By moving toward a “just what is necessary” approach, you can operate closer to actual customer demand and reduce waste through lower overproduction and inventory levels… while also reducing production costs by redeploying human resources toward new value-added activities.

Another advantage: just-in-time flows make planning, supply, maintenance, and quality issues more visible. Total quality management aims to continuously improve products, processes, and overall organizational performance by focusing on customer satisfaction. To achieve this, it relies on a team-driven approach in which employees are encouraged to proactively identify and solve problems, thus contributing to continuous process improvement. Within the same organization, employees and management alike focus on finding improvements and solutions to quality issues.

Within the Lean Manufacturing framework, a culture of collaboration emphasizes waste reduction and production process optimization. Careful planning, close coordination among departments, and precise synchronization at every stage of production make it possible to achieve high and consistent quality levels and to meet objectives efficiently. Operations become more effective and profitable, while meeting customer demand by delivering high-quality products on time and in a safe working environment.

The Fundamental Foundations of Lean Implementation

Employee Involvement and Collaboration

Lean is fundamentally a common-sense philosophy. It is essential to engage your people and encourage the organization to share good ideas. This is the first step in a cultural change process that affects all sectors, departments, and resources within the company. Empowering and involving employees also helps them buy into this approach.

Employee Safety and Standardization

Safety must be everyone’s responsibility within an organization. Reducing the risk of accidents and incidents also leads to waste reduction. This is a minimum requirement and often the first lever to improve. Standardization is the basic tool of continuous improvement. Standards formalize best practices in a simple and visual way and support knowledge transfer. Whether the goal is to continuously improve safety, quality, or any other lever, standards enable managers to sustain the system over time.

Key Performance Indicators (KPIs) and Daily Management Systems

Daily management systems and KPIs play a crucial role in implementing and monitoring Lean manufacturing.

Management systems provide the overall framework for organizing, coordinating, controlling, and managing a company’s activities. They refer to the methods, tools, techniques used, and the STANDARDS, and cover areas such as operations management, human resources management, financial management, supply chain management, and more. They help organizations operate more efficiently by optimizing resources and supporting informed decision-making.

KPIs help companies measure and track progress toward objectives that primarily focus on waste elimination, efficiency improvement, and value creation for the customer. These performance metrics can be implemented at multiple levels within your organization. In this regard, Merkur can help you validate the relevance of the right KPIs to assess your company’s true performance.

With these implementation foundations in place, you will gradually be able to analyze more deeply, define manufacturing strategies, and better address the voice of the customer, which represents customer needs at every level of the organization. Various continuous improvement tools can then be applied to achieve the expected results.

Productivity Challenges

Plant Layout

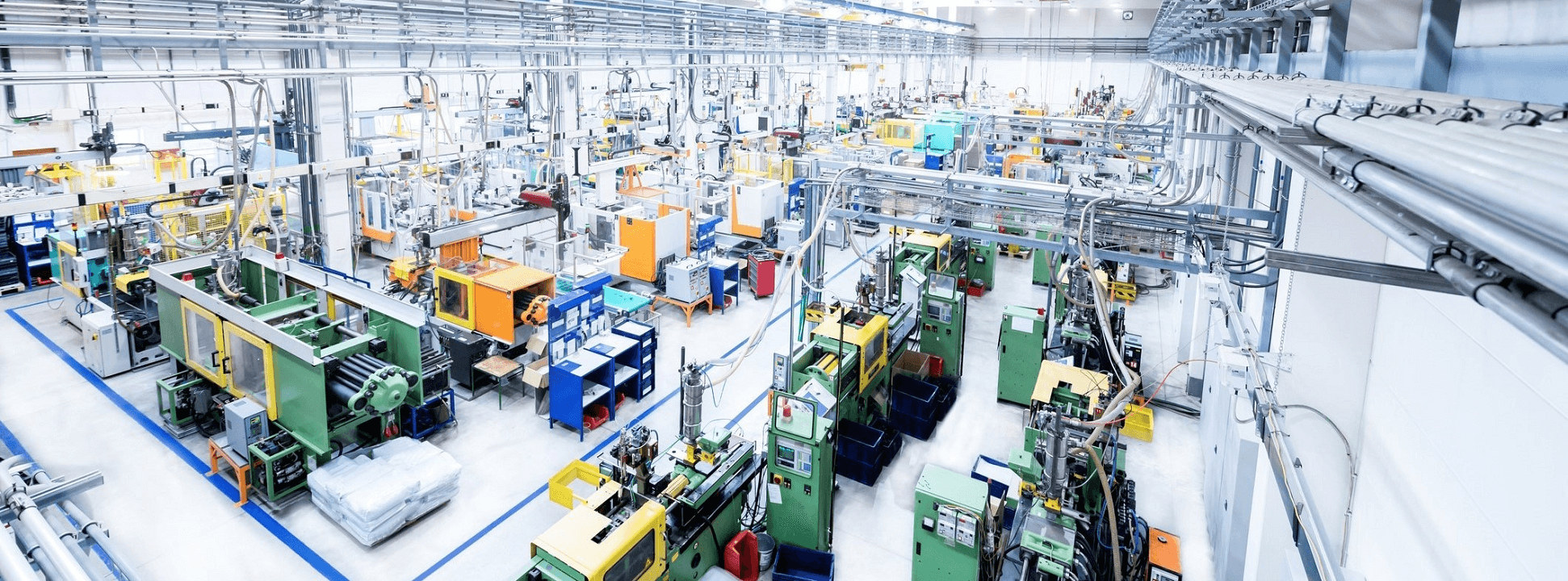

A well-designed plant layout creates a more ergonomic, highly efficient, and agile work environment while reducing the risk of accidents. In this context, the physical arrangement of machines, workstations, storage areas, and all other elements within the production facility helps improve the flow of materials and information. A well-designed plant layout is based on Lean principles by facilitating continuous workflows, communication, and collaboration among employees. It minimizes material travel distances, improves operational efficiency, and promotes more agile and flexible production—creating a work environment truly focused on value-added activities.

The Concept of Lead Time

Lead time refers to the total time required for a product to pass through all stages of the production process, from the receipt of materials to delivery to the customer. Value stream mapping makes it possible to evaluate lead time and identify bottlenecks and opportunities to reduce non–value-added activities, particularly inventory. By addressing these opportunities, you will reduce lead time and improve productivity and profitability. Improve your bottleneck, and you will increase your capacity…

Conclusion

Lean manufacturing offers companies numerous benefits, ranging from cost and waste reduction to improved quality, operational efficiency, capacity, flexibility, and employee engagement. Its success requires long-term commitment and ongoing efforts to transform company culture and processes. This culture of continuous improvement—where organizations constantly seek ways to optimize operations and create value for customers—encourages innovation and the exploration of new approaches, such as digital solutions.

Would you like to experience the benefits of Lean?

Our experts have developed an engaging training program, “Introduction to Lean and Continuous Improvement,” designed to apply Lean concepts while strengthening team cohesion by assembling small LEGO fire trucks on our connected Industry 4.0 production line.

Our Merkur experts can support you—don’t hesitate to contact them.