Accelerating the Production Launch of a Oneka Desalination Buoy

- Client

- Oneka Technologies

- Sector

- Marine

- Expertise

- Product Development

- Logistics and Supply Chain

CONTEXT

CHALLENGES

ASSIGNMENT

Oneka sought to integrate several experts in procurement and in product development.

These Merkur experts complemented Oneka’s team and supported the planning of manufacturing through its supplier network, as well as the production launch of the buoy.

RESULTS

Project delivery on time and within budget

OBJECTIVE AND ACHIEVEMENT

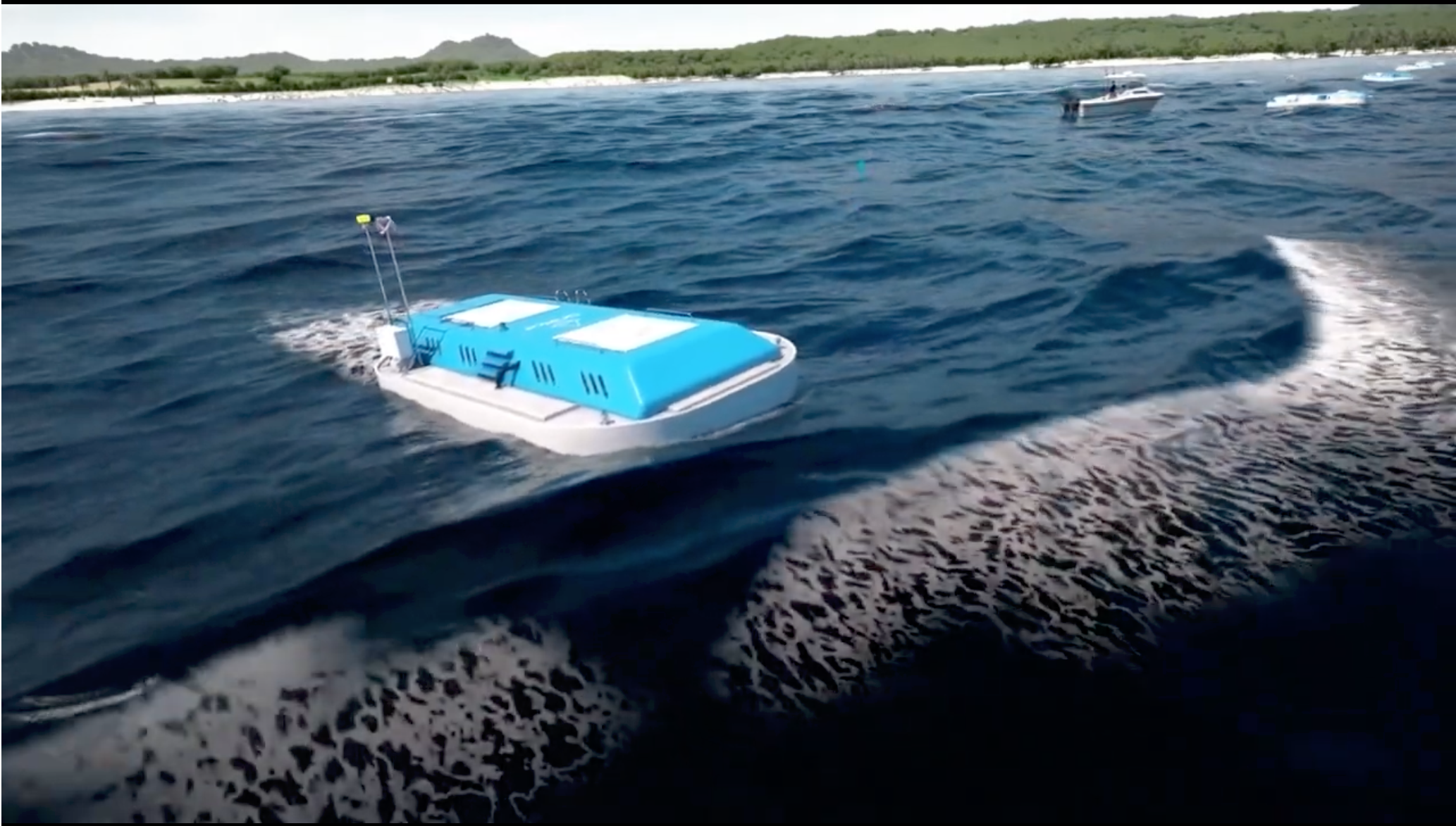

Manufacture a prototype of a new generation of desalination buoys

Manufacture a prototype of a new generation of desalination buoys

- Support the team in project management and in identifying manufacturing and assembly partners for the buoy.

-

Support the organization of engineering activities.

-

Provide management with visibility into project progress and achievement of objectives.

-

Maximize the use of Oneka Technologies’s grant.

TOOLS AND TECHNIQUES

Project schedule

Upfront cost estimation

Liaising between engineering and suppliers

Managing the buoy’s bill of materials (BOM)

Implementing KPIs to track progress of engineering and procurement deliverables

Coordinating bid and quotation activities with the project team

Organizing payment and delivery terms

Our collaboration with Merkur allowed us to increase our capacity during a critical period when our staffing needs exceeded our ability to recruit. Merkur’s team quickly integrated into our organization, followed our guidance, rolled up their sleeves, and delivered added value from day one. Thank you for this great experience!

Susan Hunt

Chief Innovation Officer

Oneka Technologies

DISCOVER OUR PROJECTS

Optimization of Bus Handling Equipment

Transportation

One of our customers, a manufacturer of passenger buses and motor homes, decided to replace the ferries in its passenger bus assembly plant.

Integration of an Electronic Module for Motorized Watercraft

Electrification

Merkur worked with one of its customers, a manufacturer of motorized watercraft and recreational vehicles, to modernize one of its pieces of equipment.

Design and simulation for the passenger seats of the Long Island Rail Road In New-York

Transportation

Developed for daily commuters on New York’s suburban rail lines, the M9 seats were manufactured by our client, Khrome PT, on behalf of Kawasaki. The twofold objective was to meet strict transportation safety standards while also complying with the railcar manufacturer’s technical specifications—all within the established budget.