Automatic stacker design for Plafonds Embassy

- Client

- Plafonds Embassy

- Sector

- Manufacturing

- Expertise

- Industrial Project Management

- Tooling and Equipment Design

- Manufacturing Simulation

CONTEXT

CHALLENGES

ASSIGNMENT

Although equipped with a lifting platform, Plafonds Embassy did not know how best to use it to achieve this stacking, nor which operating principle to adopt.

The company called on Merkur to help clarify its needs and to research and select a solution to address this challenge. An innovative approach will allow the platform to be adapted to their specific process, thereby addressing their issue and ensuring production continuity.

RESULTS

2

times more production capacity

OBJECTIVE AND ACTIONS

Develop a tailor-made sheet stacking solution adapted to the customer's equipment pool

Develop a tailor-made sheet stacking solution adapted to the customer's equipment pool

Develop equipment capable of keeping up with the upstream laminator’s throughput, minimizing downtime and labor requirements for the operation, designing a solution that is easy to integrate from an automation standpoint, and producing clear drawings to support outsourced manufacturing.

- Workshop to map the targeted sequence of operations

- Identify issues, specifications and constraints

- Conduct technology watch

- Preliminary analysis of 3 solutions, including advantages, disadvantages and technological risks

- Mechanical design of a fully customized equipment based on the recommended solution

- Simulation of the chosen solution to parameterize the mechanisms

- Coordination with automation supplier and follow-up during start-up

TOOLS AND TECHNIQUES

Design on Solidworks

Simulation on FlexSim

We had to determine how the stacker would operate when a new piece of equipment was introduced. Merkur was able to offer us a solution that met our needs, and to support us in its development.

Alexis Boulanger

President

Plafonds Embassy

DISCOVER OUR PROJECTS

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

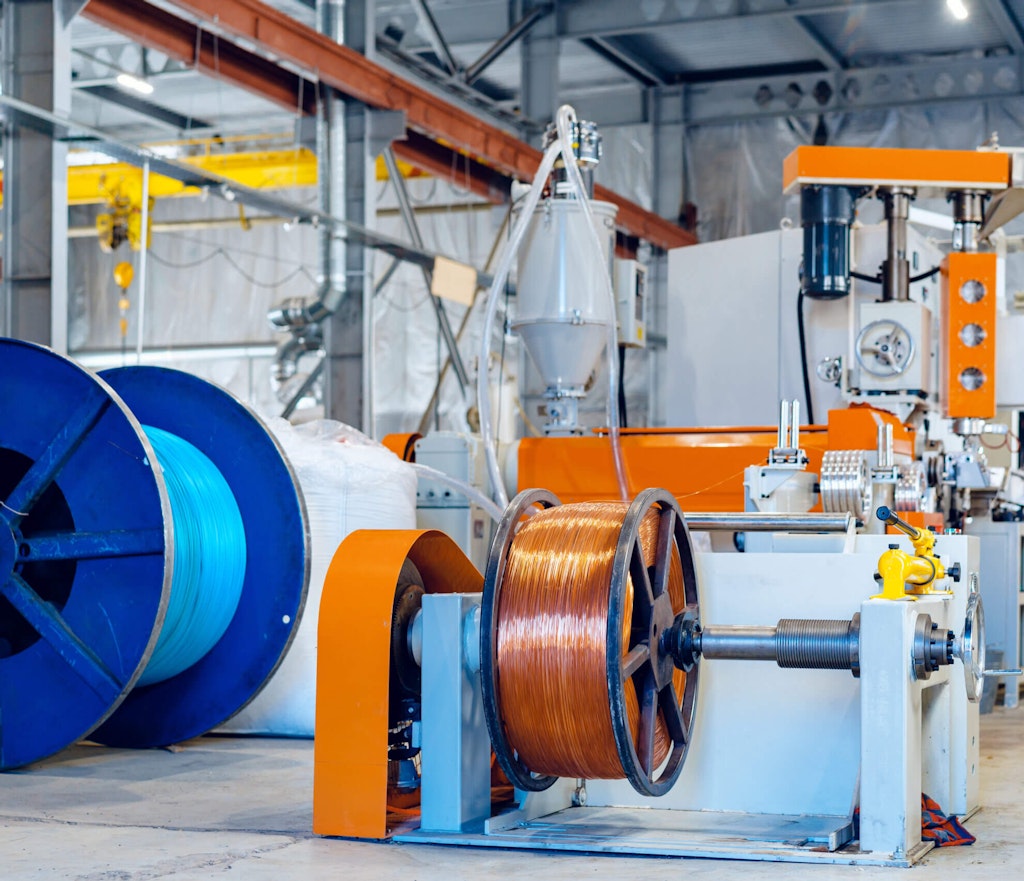

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Support for pontoon boat design and manufacturing

Manufacturing

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.