Design of Tooling to Support the Recreational Boat Production Line

- Client

- Confidential

- Sector

- Manufacturing

- Expertise

- Tooling and Equipment Design

CONTEXT

CHALLENGES

ASSIGNMENT

Merkur accompanied its client in the production of a new range of recreational boats: Aluminium Pontoons and Boats.

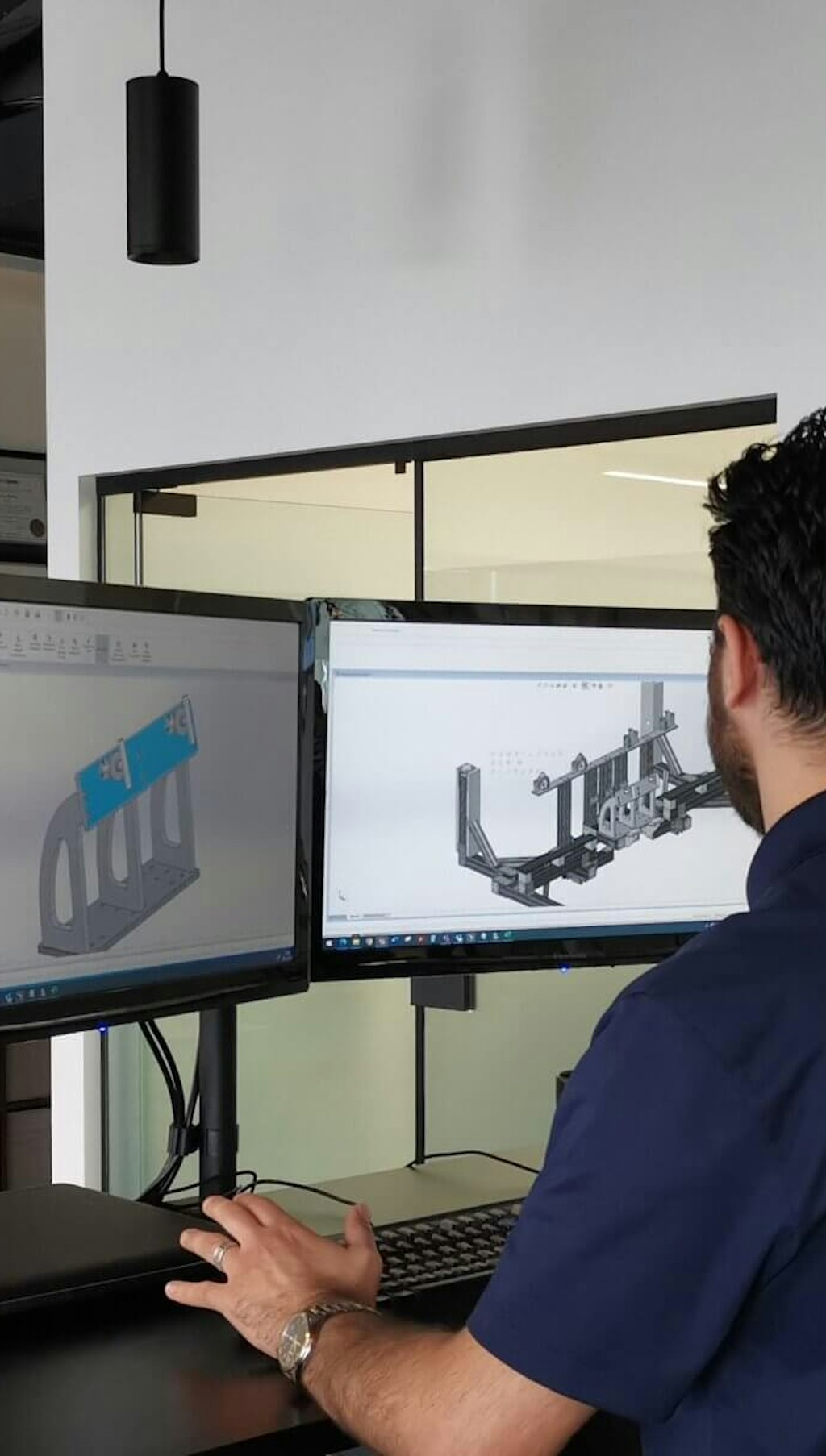

In helping to understand and analyze its production line, Merkur was involved in the design of jigs. The purpose of these jigs was to position and hold the parts together during the assembly stages.

RESULTS

50

different tools designed

OBJECTIVE AND ACTIONS

Launch new products each year by increasing production pace through the design of new tooling.

Launch new products each year by increasing production pace through the design of new tooling.

TOOLS AND TECHNIQUES

Design of a mobile assembly fixture with pneumatic option

Design of a production fixture with reversal option

Participation in the development of specifications and monitoring their evolution

Flexible team with scalable capacity

DISCOVER OUR PROJECTS

Automatic stacker design for Plafonds Embassy

Manufacturing

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

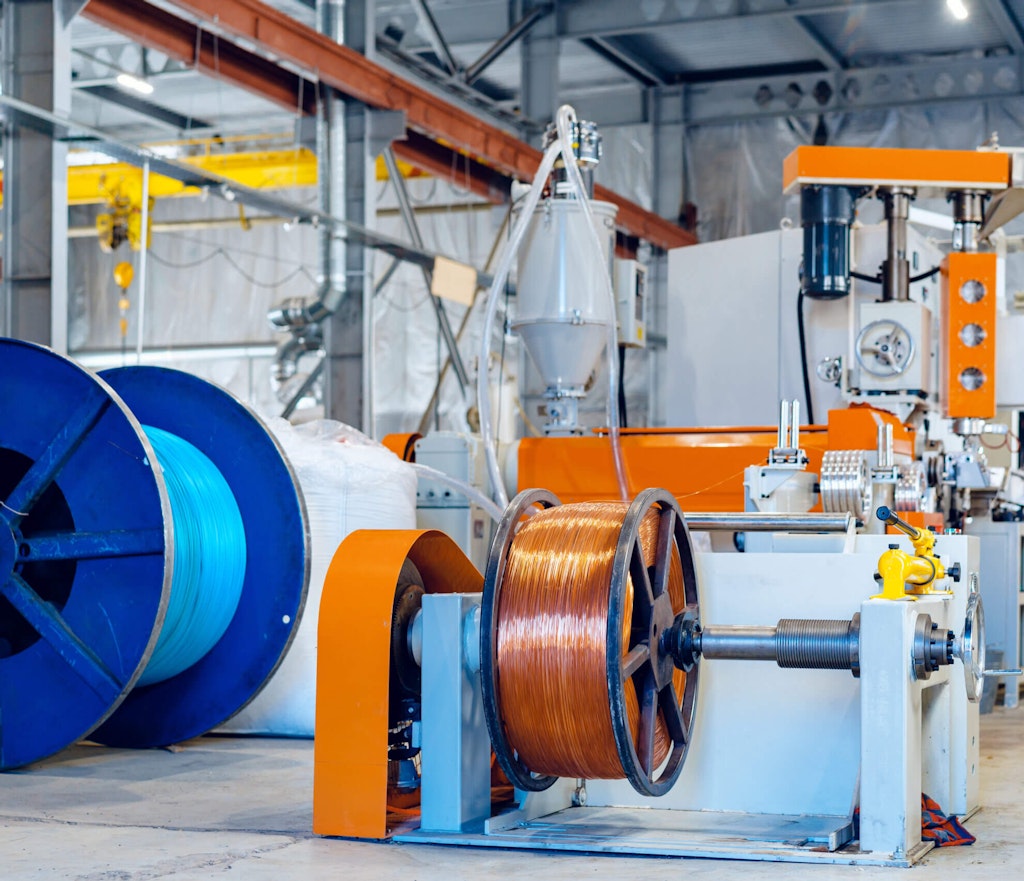

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Optimization of Bus Handling Equipment

Transportation

One of our customers, a manufacturer of passenger buses and motor homes, decided to replace the ferries in its passenger bus assembly plant.