Industrial plant expansion project at LPM

- Client

- LPM

- Sector

- Manufacturing

- Expertise

- Operational Excellence

CONTEXT

CHALLENGES

ASSIGNMENT

The collaboration with Merkur stemmed from the need to ensure that no important elements were overlooked in the new layout.

LPM needed to optimize flow and space, eliminate waste and define a more efficient work organization.

RESULTS

25 %

efficiency improvement in supply-receipt-acquisition

OBJECTIVE AND ACHIEVEMENT

Define new factory layout using industry best practices

Define new factory layout using industry best practices

- Challenge the LPM team with Lean methodology

- Define and implement the optimum layout

- Optimize flows

- Limiting waste

- Defining space and efficient work organization

TOOLS AND TECHNIQUES

Brainstorming

KANBAN

Relationship diagram

High-frequency supply

Design criteria matrix

OUR PROJECT IN ACTION

Our decision to expand the plant to accommodate our constant growth brought with it its share of challenges and opportunities. Merkur's ability to involve the company's key players and constantly challenge everyone's ideas enabled us to successfully fulfill the mandate.

Stéphane Boisjoli

President

LPM

DISCOVER OUR PROJECTS

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

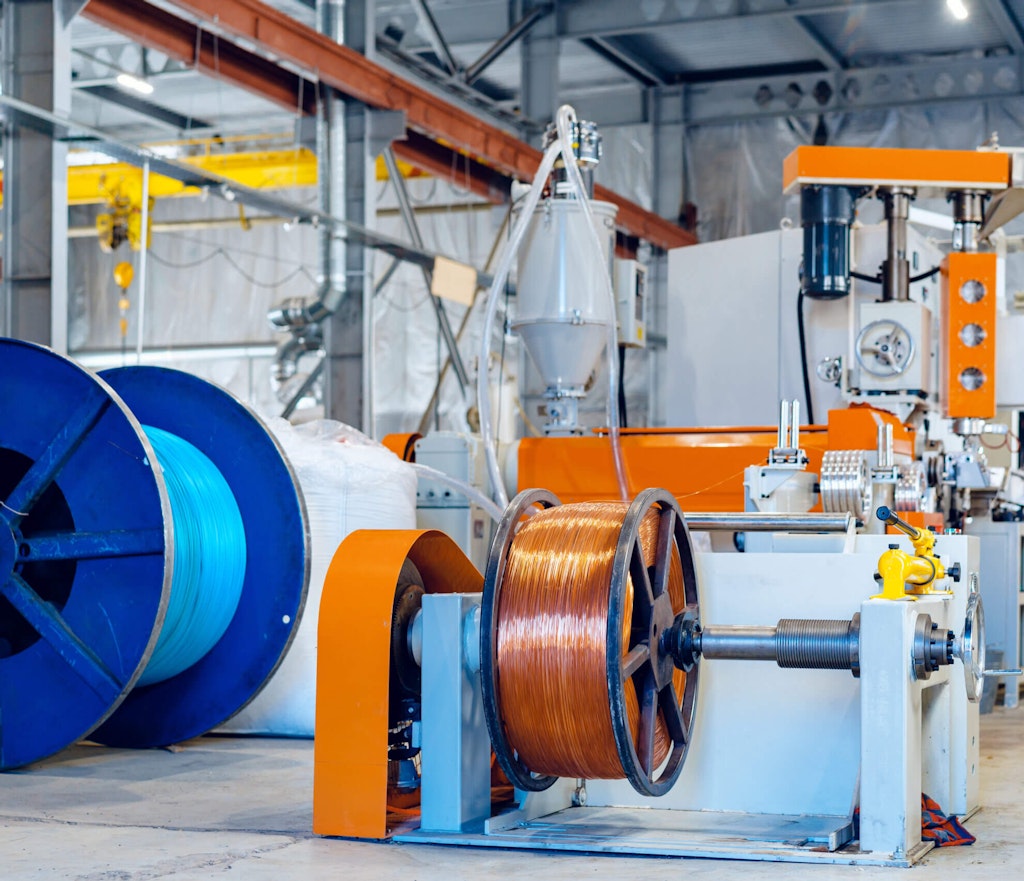

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Support for pontoon boat design and manufacturing

Manufacturing

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.