Matritech: A Large-Scale 4.0 Turnaround

- Client

- Matritech

- Sector

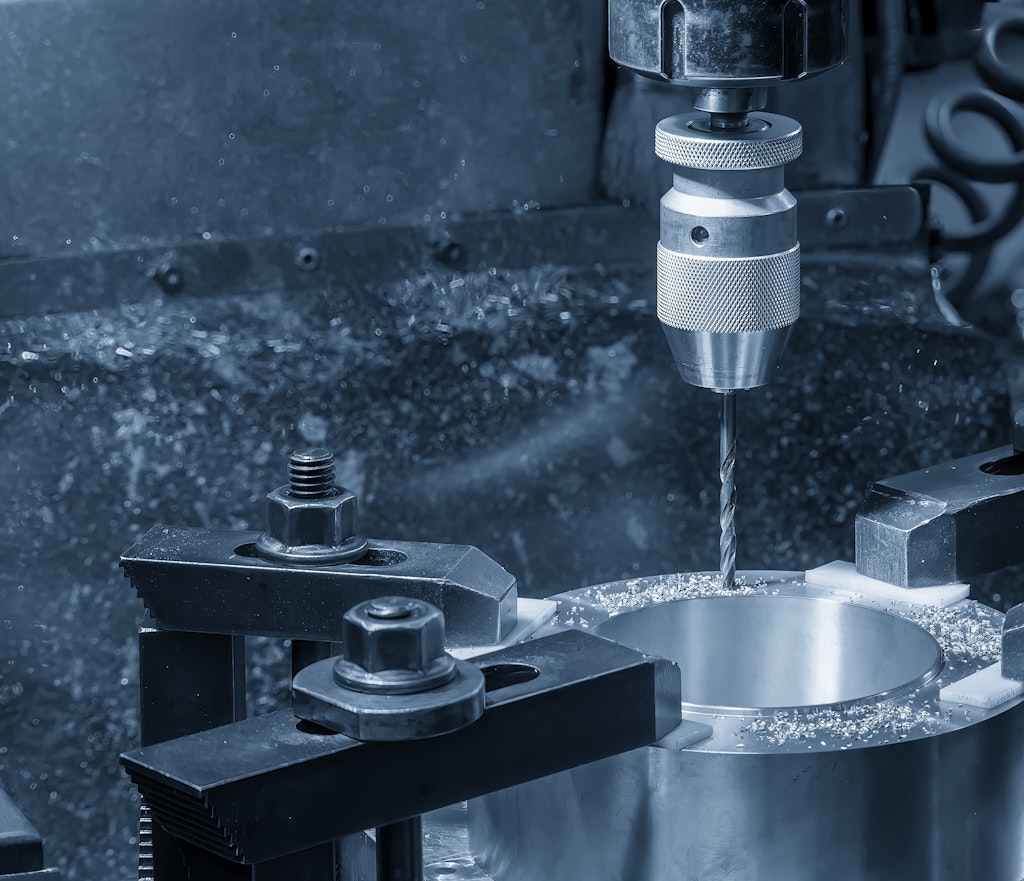

- Manufacturing

- Expertise

- Operational Systems Management

- Digital project management

CONTEXT

CHALLENGES

ASSIGNMENT

Digital Strategy and Operational Excellence: A Winning Combination!

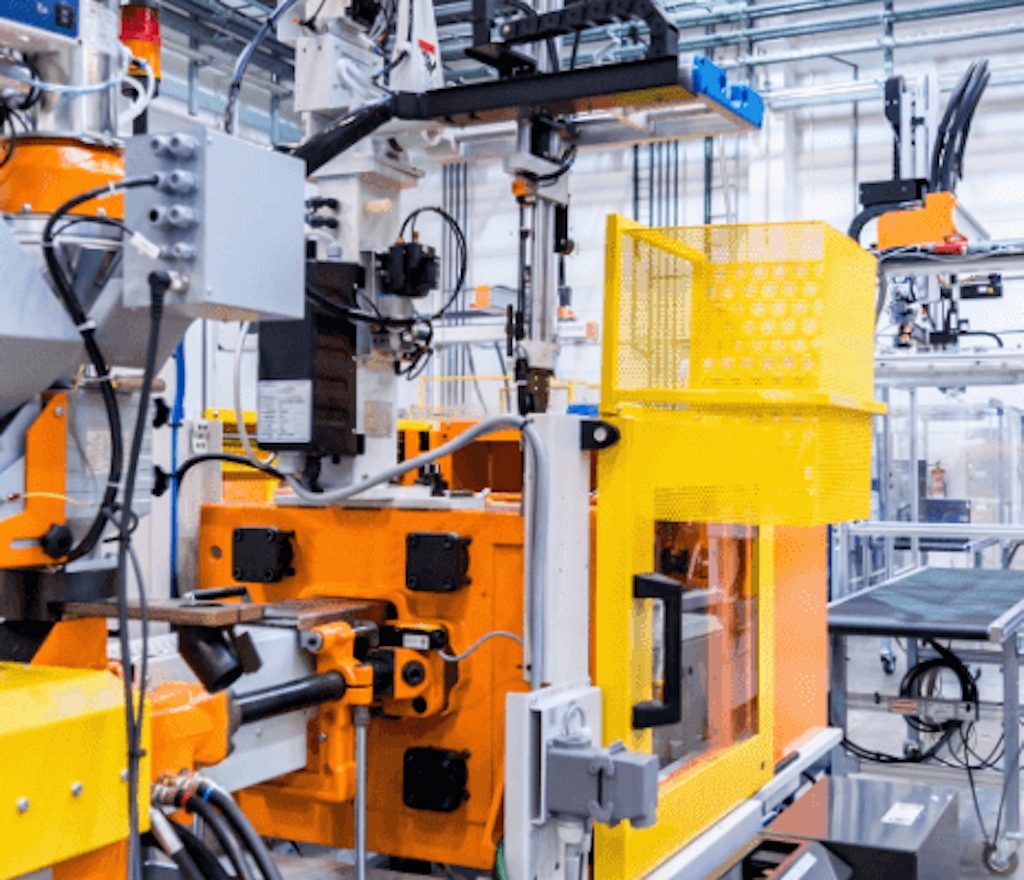

The intervention aimed to improve overall plant performance by deploying a scalable technological solution, using a real-time virtual manager to support the production team in daily operations, and ultimately increasing efficiency and productivity.

RESULTS

30

machines connected and integrated with data from the ERP system

OBJECTIVE AND ACTIONS

The most interesting digital opportunities for Matritech were first identified and then deployed, notably in the field of the smart factory and machine data acquisition and exploitation.

The most interesting digital opportunities for Matritech were first identified and then deployed, notably in the field of the smart factory and machine data acquisition and exploitation.

The preferred strategy at Matritech was the use of the small project approach.

This approach generated quick wins while supporting a gradual organizational change. Merkur supported Matritech in reviewing its value chain to identify priorities and define a clear technological and operational strategy.

The implementation of the SYNKRO platform connected machine data to the ERP system, providing a real-time view of production through more than thirty connected machines. Despite the diversity of equipment, SYNKRO enables efficient use of all available data.

TOOLS AND TECHNIQUES

SYNKRO software (collects, processes and distributes digital data from the production floor in real time)

Roadmap system

By achieving a level of intelligent coordination between machines and humans, Matritech will be among those pioneers who dare to implement new ways of doing things in the industry!

Merkur

DISCOVER OUR PROJECTS

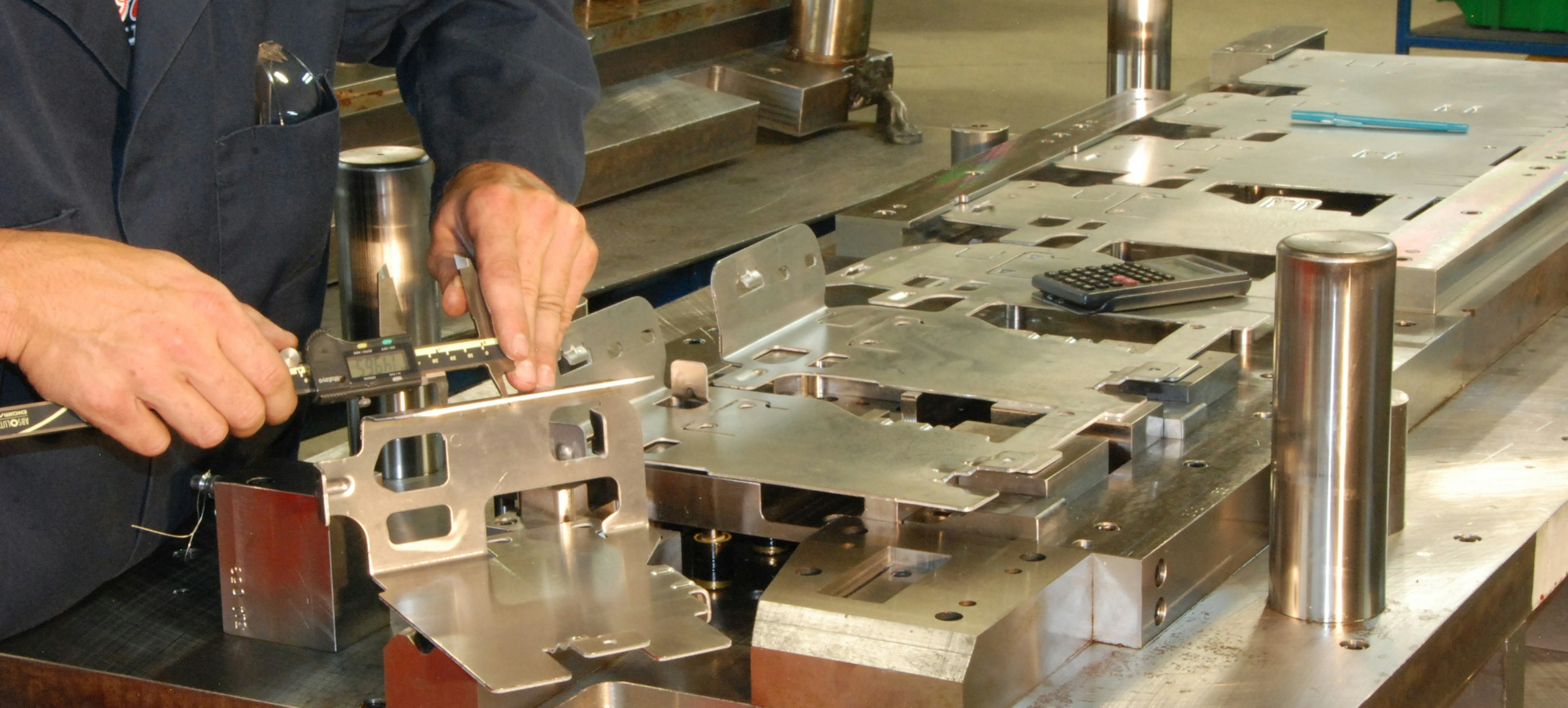

A successful digital transition for Metalus’s new smart factory

Manufacturing

Metalus specializes in sheet metal fabrication. The company, which has seen steady growth since 1988, found itself at an impasse created by a logistics problem: its 125 employees were having to manually distribute more than 1000 work orders a week.

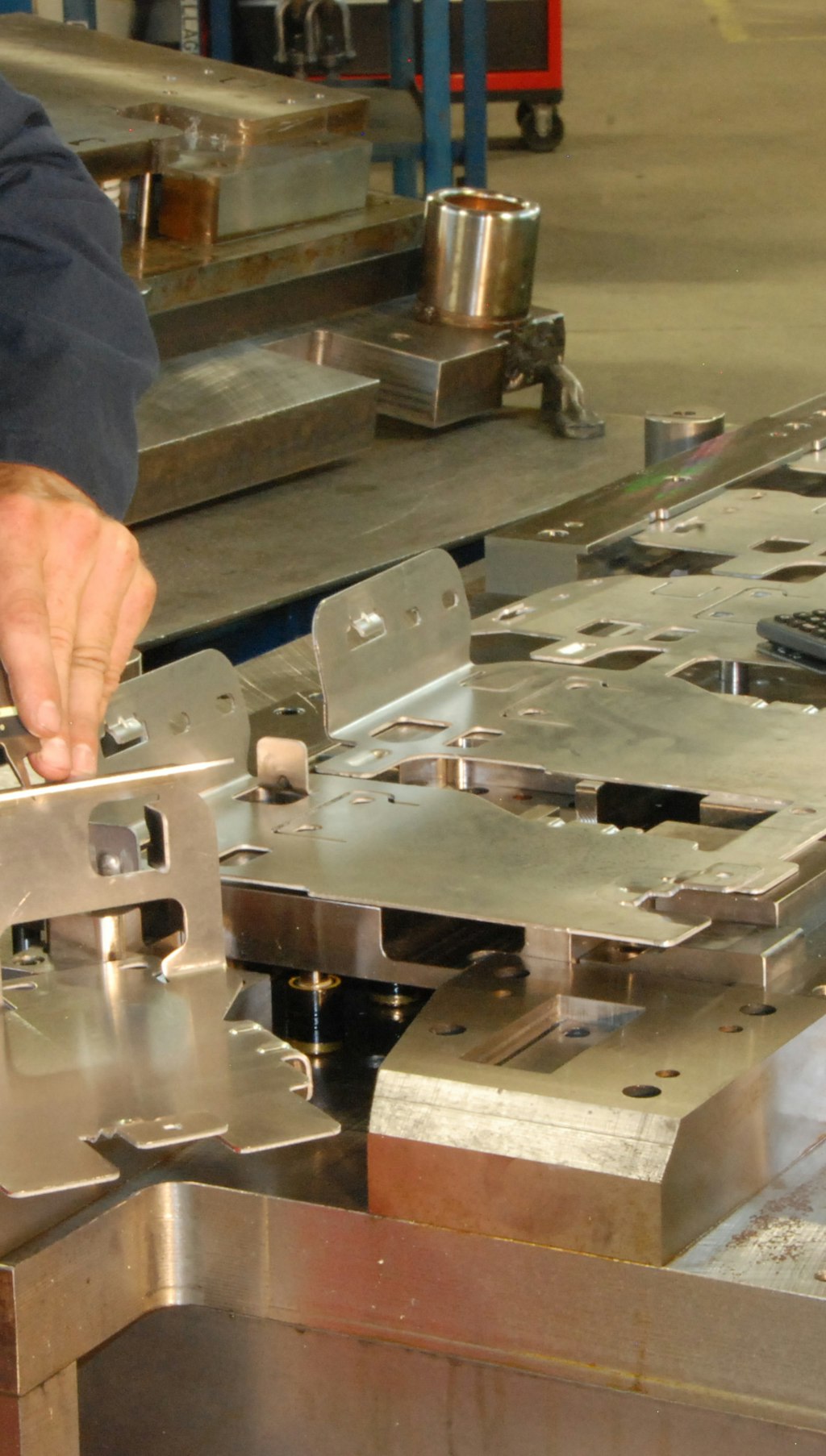

Lemay Outillage Successfully Turns Digital

Manufacturing

Lemay Outillage specializes in supporting the design and manufacture of tooling. The company was seeking to strengthen the exchange of information between production employees, gain better real-time visibility into the performance of its machinery, and make significant progress toward its vision of a connected factory.

Digital transformation made easy with the SYNKRO® connectivity solution

Manufacturing

Our client, a world leader in chemical processes, wanted to eliminate paper from their production floor. They decided to implement SYNKRO in order to automate certain processes, therefore avoiding having to manually transcribe information for various systems in place.