Optimisation of a new plant’s secondary operation lines

- Client

- Confidential

- Sector

- Transportation

- Expertise

- Industrial Project Management

CONTEXT

CHALLENGES

ASSIGNMENT

Optimize mixed production of complex parts

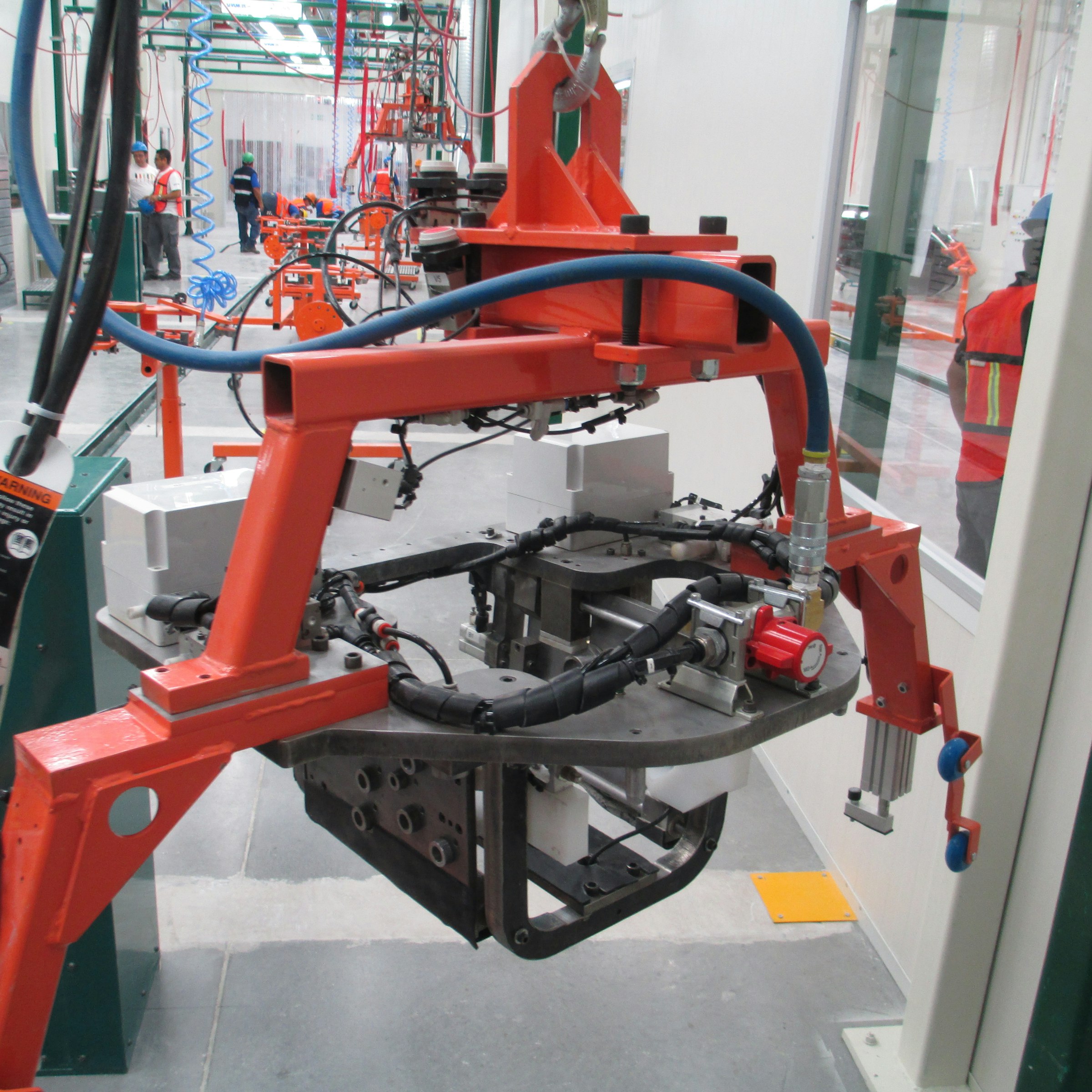

More specifically, design 80 different versatile templates to optimise and ensure the mixed production of approximately 15 different models of parts in unitary flow, many of which will have up to 150 holes, not to mention the multiple cut-outs and characteristics specific to each model.

RESULTS

15

Different part models

OBJECTIVE AND ACTIONS

Optimisation of this new secondary operation line

Optimisation of this new secondary operation line

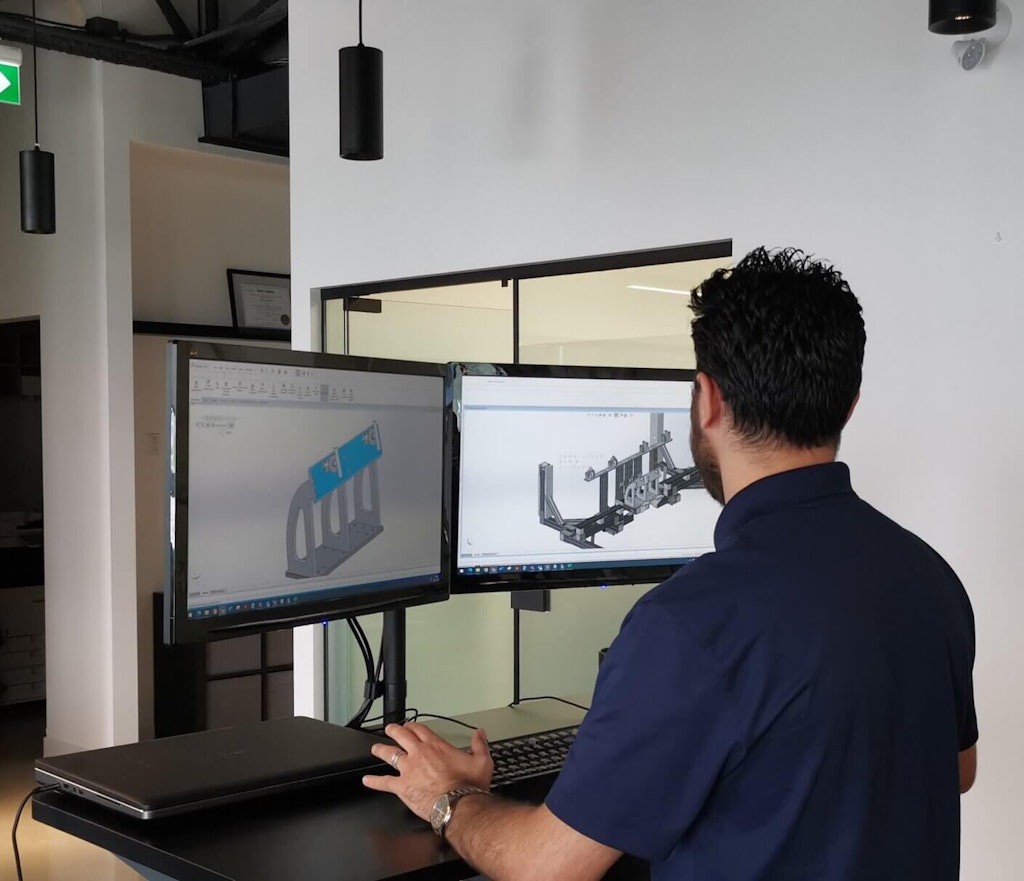

Merkur has brought together its experts in tooling design, manufacturing engineering and operational excellence to precisely develop advanced, automated tooling that reduces set-up times, avoids human error, and improves the overall performance of our customer’s operations.

Merkur

DISCOVER OUR PROJECTS

Masonite doubles its factory production capacity and reduces delivery time by 30%

Manufacturing

Lemieux Doors (now the property of Masonite) specializes in the manufacture of wooden doors. After many years of strong growth, the company found itself dealing with a new industry trend: customization.

Design of Tooling to Support the Recreational Boat Production Line

Manufacturing

The recreational boat industry is a highly competitive market where product customization is essential. The partnership between Merkur and its customer has enabled the latter to implement the solutions best suited to its needs.

Automation Strategy for a New Production Line

Manufacturing

Merkur worked with its client, an electronic components manufacturer, to implement an automation strategy for its new production line by deploying an operations simulation using FlexSim®.