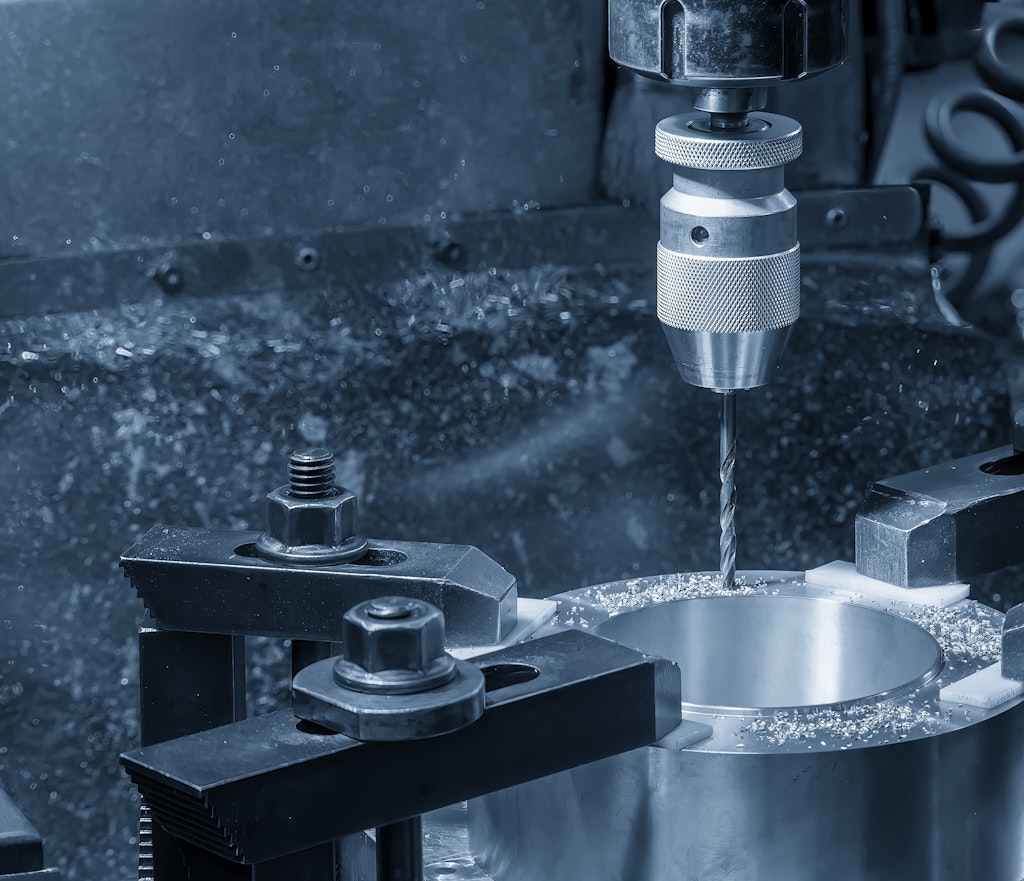

Standardizing Production Through Digital Transformation

- Client

- Canam Ponts

- Sector

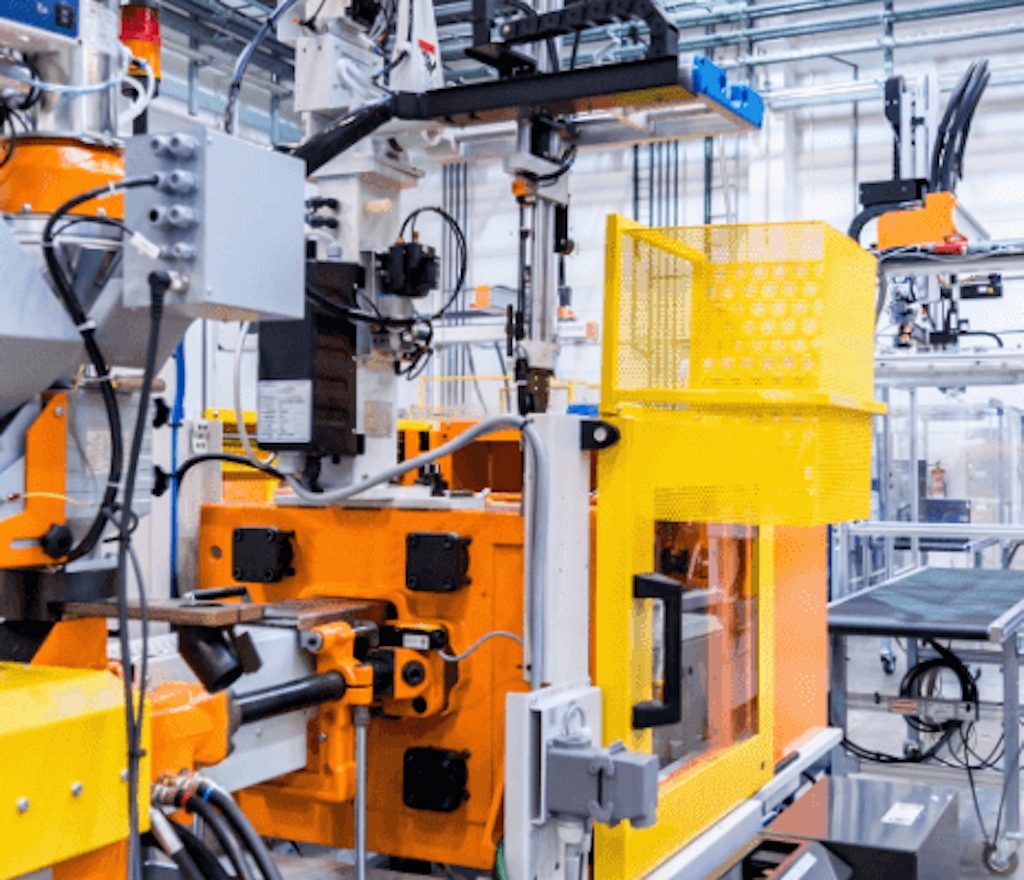

- Manufacturing

- Expertise

- Operational Process Optimization

- Operational Systems Management

CONTEXT

CHALLENGES

ASSIGNMENT

The implementation of our SYNKRO software in each of the three plants.

OBJECTIVE AND ACTIONS

The implementation of our SYNKROsoftware in each of the three plants allowed us to gather a maximum of information to align the manufacturing strategies.

The implementation of our SYNKROsoftware in each of the three plants allowed us to gather a maximum of information to align the manufacturing strategies.

This information includes utilization rate, machine alarms, welding data and real-time machining status. It is now easier for our client to consolidate the information collected in each of its plants, regardless of machine type. This allows them to have a better visibility on what is happening in the plant with the help of web dashboards, which can be accessed remotely.

TOOLS AND TECHNIQUES

reation of real-time dashboards for better visibility of machine status

Personalized support with the client's IT team for complete autonomy in connecting machines and designing dashboards according to their needs

Canam Group now has the necessary tools to pursue their continuous improvement, while having an overview of the operations of the three plants

Merkur

DISCOVER OUR PROJECTS

A successful digital transition for Metalus’s new smart factory

Manufacturing

Metalus specializes in sheet metal fabrication. The company, which has seen steady growth since 1988, found itself at an impasse created by a logistics problem: its 125 employees were having to manually distribute more than 1000 work orders a week.

Lemay Outillage Successfully Turns Digital

Manufacturing

Lemay Outillage specializes in supporting the design and manufacture of tooling. The company was seeking to strengthen the exchange of information between production employees, gain better real-time visibility into the performance of its machinery, and make significant progress toward its vision of a connected factory.

Digital transformation made easy with the SYNKRO® connectivity solution

Manufacturing

Our client, a world leader in chemical processes, wanted to eliminate paper from their production floor. They decided to implement SYNKRO in order to automate certain processes, therefore avoiding having to manually transcribe information for various systems in place.