Supplier selection for Dettson: Combining procurement expertise and electrical engineering support

- Client

- Dettson

- Sector

- Manufacturing

- Expertise

- Logistics and Supply Chain

- Electrical and Electronic Engineering

CONTEXT

CHALLENGES

ASSIGNMENT

Dettson expressed the need for an electronics engineering resource.

After understanding the context, Merkur decided that procurement expertise would be more appropriate to bring the project to fruition, while retaining the technical expertise of electronic engineering.

RESULTS

Cost reduction vs. customer's estimated budget

OBJECTIVE AND ACTIONS

Taking charge of the procurement project

Taking charge of the procurement project

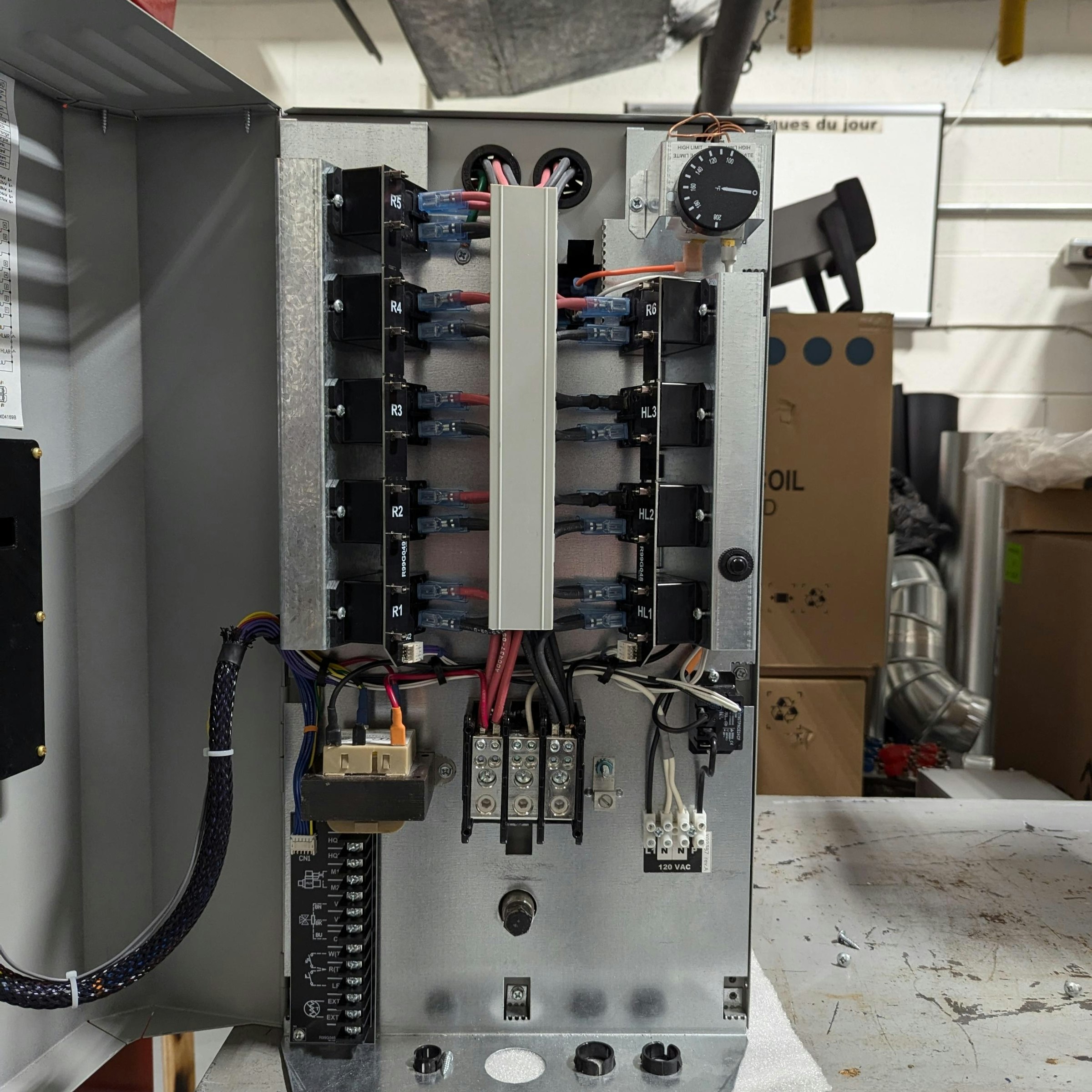

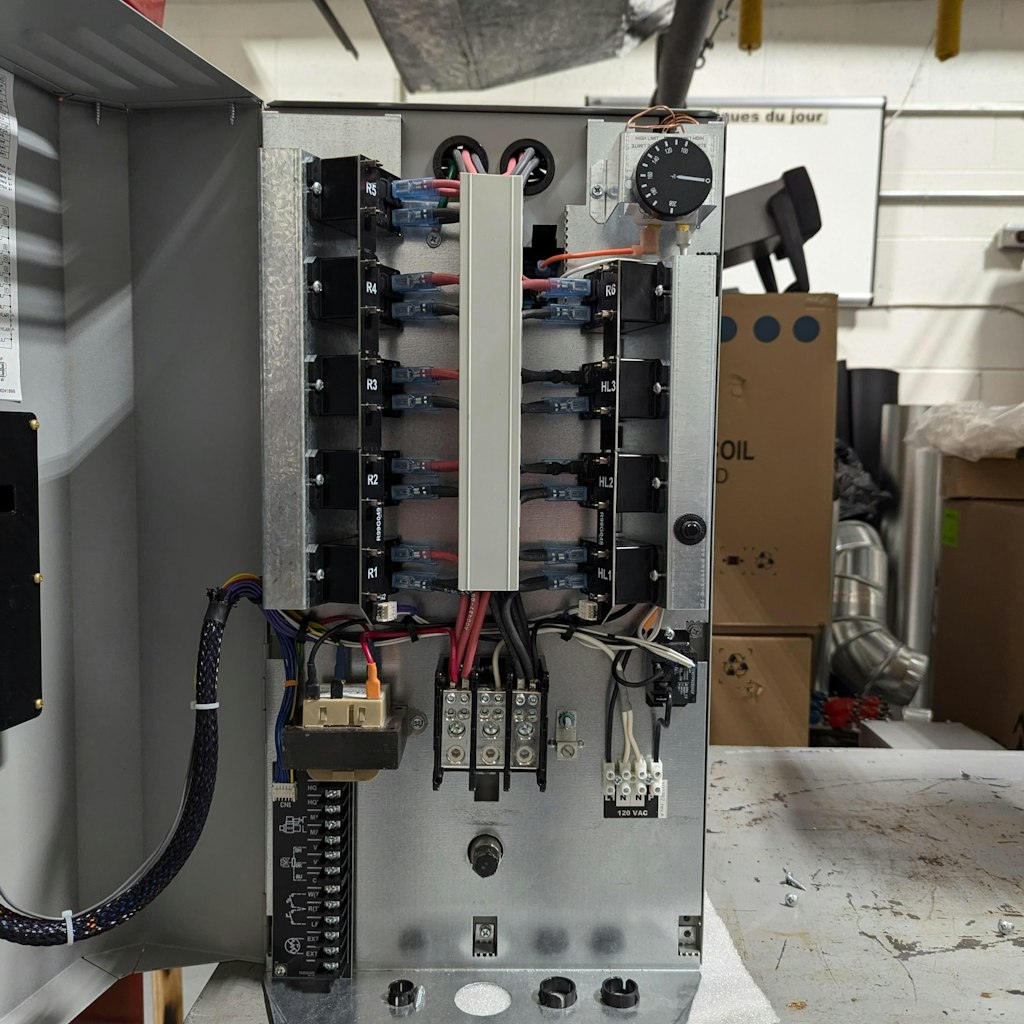

Understand the customer's qualification criteria “for the manufacture and assembly of an electronic board dedicated to a new family of electric boilers”, while respecting the customer's budget and deadline.

- Define key project issues

- Understand the required product

- Target and suggest modifications to technical specifications to the customer

- Negotiate and seek gains with the selected supplier

TOOLS AND TECHNIQUES

Bidding and supplier selection tools (selection grid, bid templates, scoring and supplier selection recommendations)

Pre-qualification audit. Ensure compliance with the customer's quality criteria for supplier selection

Analyze technical specifications from each supplier

Merkur quickly made resources available to us for an important and urgent project. The exchanges were quick, which enabled us to complete this project in record time. Even though the bids fell short of the target, Philippe went back to the supplier and asked for additional discounts.

Philippe Verhas

R&D Director

Dettson

SEE OUR PROJECTS

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

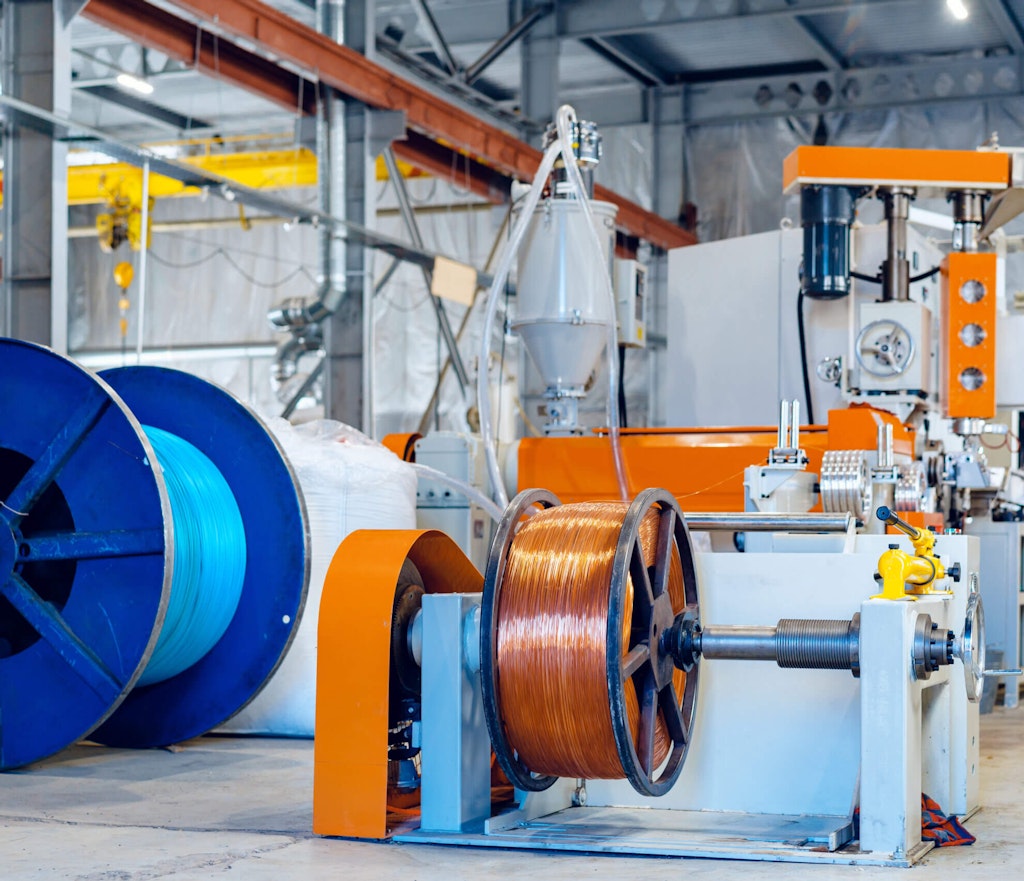

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Support for pontoon boat design and manufacturing

Manufacturing

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.