Support for pontoon boat design and manufacturing

- Client

- Confidential

- Sector

- Manufacturing

- Expertise

- Product Development

CONTEXT

Our customer, a manufacturing company specializing in recreational products, had the opportunity to expand its production capacity. This expansion enabled the group to which it belongs to offer quality pontoons through its American sister company, thus increasing its market share.

CHALLENGES

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

ASSIGNMENT

Design and manufacture locally a new pontoon boat, while preserving the DNA of the American brand.

To seize this opportunity, our customer needed external support by adding a Merkur project manager to its existing team.

RESULTS

3

high-quality prototypes delivered on time

OBJECTIVES AND ACHIEVEMENT

Accompany the customer in the implementation of this project, from product development to production launch.

Accompany the customer in the implementation of this project, from product development to production launch.

- Offer a senior project management resource with outsourced product development expertise in-house.

- Establish product specifications with the customer's sister company and ensure that the number of options is reduced to be more efficient on the assembly line, and reduce costs.

- Draw up functional specifications.

- Draw up a schedule to deliver the first three prototypes by a given date.

- Ensure that the DNA of the sister company is respected in the design and manufacture of the pontoon.

- Follow-up with suppliers.

- Set weekly priorities for engineering teams and tests.

- Support industrialization and production teams throughout the product development process.

TOOLS AND TECHNIQUES

“BOM Builder" to evaluate the cost of options in relation to the customer's perceived value

Quality criteria for supplier part acceptability

Establishment of DFMA criteria and meetings in the product development process

Team management

Change management

Stakeholder management, communication plan

This was a challenging project full of responsibilities that allowed me to participate in the entire product development process, from ideation with the customer to delivery of the product to distributors. Merkur, in close collaboration with our partner, provided technical and strategic assistance throughout the project, ensuring that each stage was completed in line with the planned deliverables to ensure the success of the project.

Geneviève Masson, Eng., Ph.D.

Director, Engineering and Product Development

Merkur

DISCOVER OUR PROJECTS

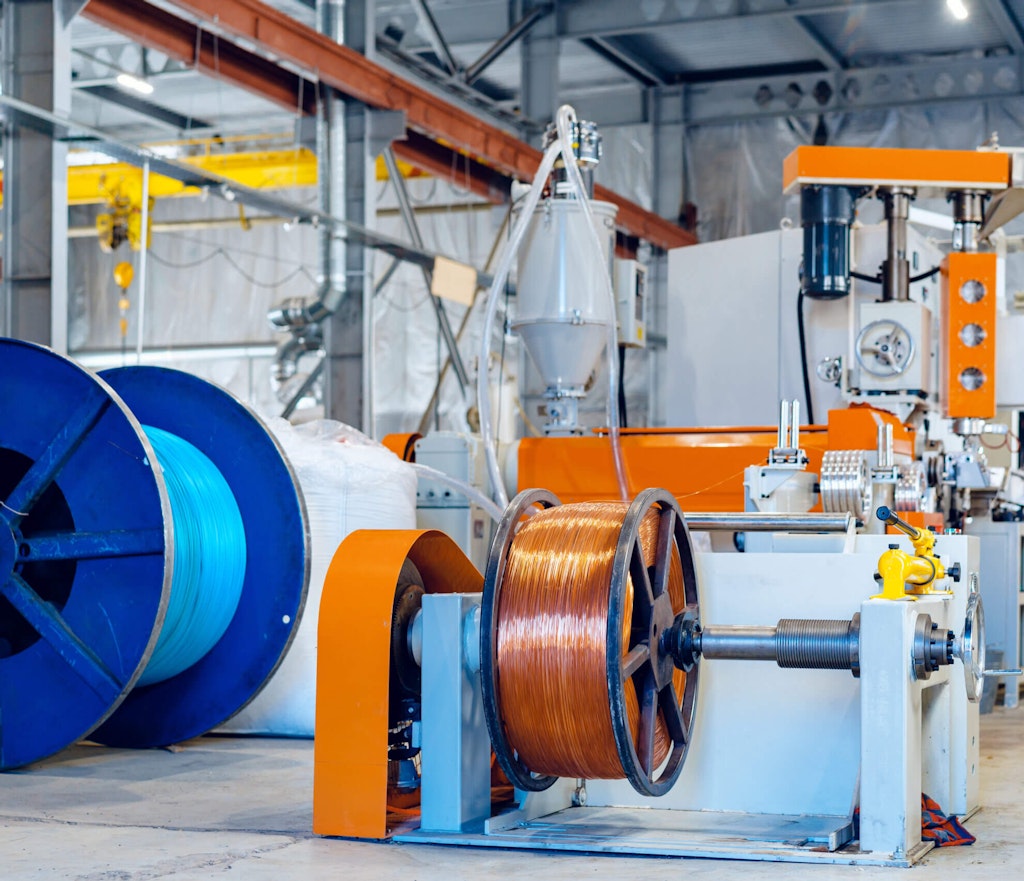

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.

Lemay Outillage Successfully Turns Digital

Manufacturing

Lemay Outillage specializes in supporting the design and manufacture of tooling. The company was seeking to strengthen the exchange of information between production employees, gain better real-time visibility into the performance of its machinery, and make significant progress toward its vision of a connected factory.