Warehouse Consolidation and Design of a Multisite Logistics Network

- Client

- Confidential

- Sector

- Manufacturing

- Expertise

- Logistics and Supply Chain

CONTEXT

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.

CHALLENGES

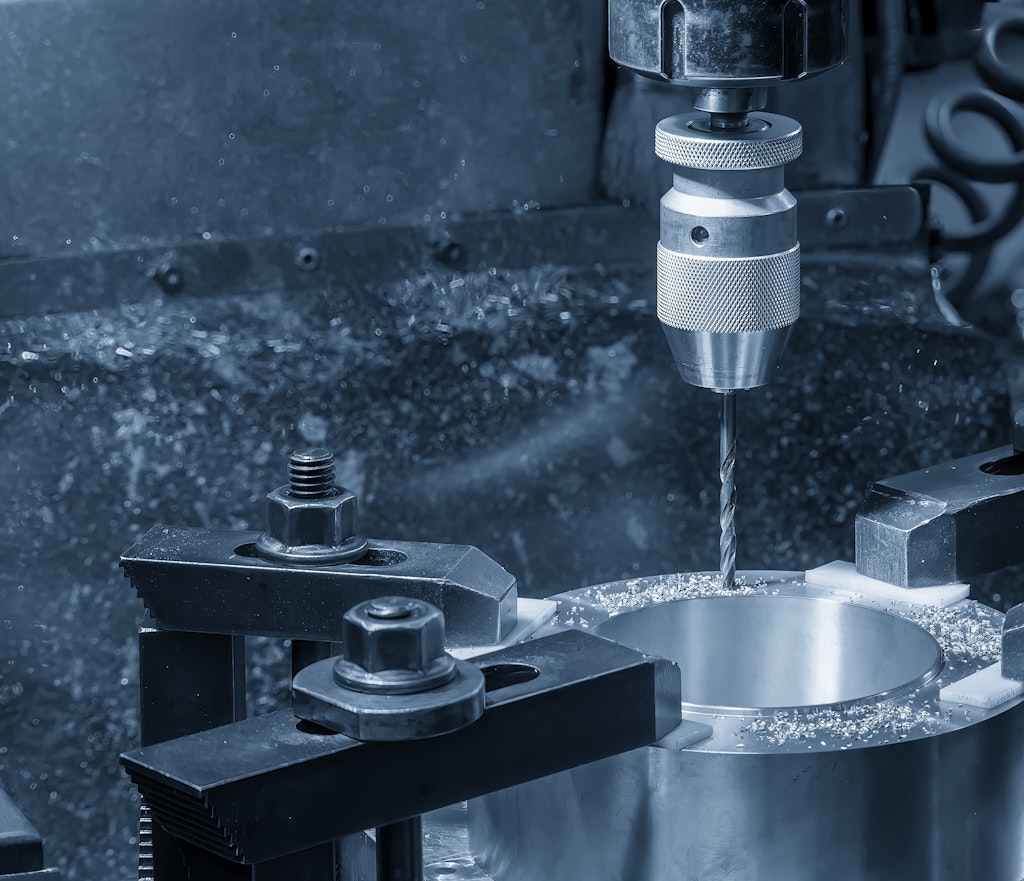

To support this increase in volume, the company shifted its manufacturing strategy from a single-site model to a multisite approach.

ASSIGNMENT

Our customer asked Merkur to develop an optimized multi-site logistics strategy.

The company had three small, inefficient, and over-capacity warehouses located near the production sites. With the increase in production, this strategy became untenable as it would require a further increase in the number of warehouses.

RESULTS

Growth Increased logistics capacity enables production to be doubled

OBJECTIVE AND ACHIEVEMENT

Increase production capacity a solution that optimizes cost and performance

Increase production capacity a solution that optimizes cost and performance

- Determine the required warehouse area to centralize component storage and optimize space utilization.

- Define an inter-site logistics strategy to deliver components to the main factory from the warehouse and the second production site.

- Determine current issues and waste in warehouses and the logistics network.

- Define the ERP requirements (inventory status and location, planning, stock in transit, etc.)

- Define and identify the logistics master data required for the ERP (locations, material groups, and storage capacities)

TOOLS AND TECHNIQUES

Lean Manufacturing

Warehouse Design

High-Frequency replenishment

KANBAN

Business process mappings

ERP requirements

Our customer, a long-standing partner, undertook a rapid strategic expansion requiring an accelerated transformation of its production and logistics. The objective was to optimize costs while ensuring high operational efficiency.

Mohamad Kabbara

Operational Excellence Consultant

DISCOVER OUR PROJECTS

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

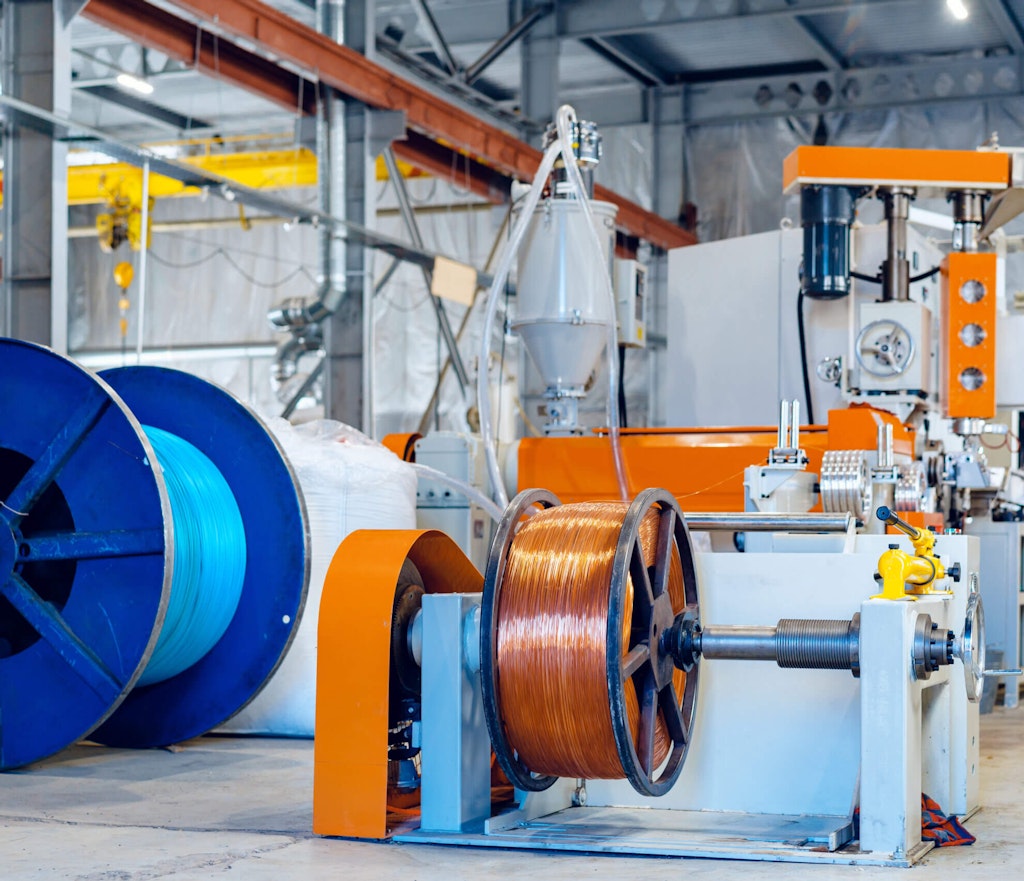

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Support for pontoon boat design and manufacturing

Manufacturing

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

Lemay Outillage Successfully Turns Digital

Manufacturing

Lemay Outillage specializes in supporting the design and manufacture of tooling. The company was seeking to strengthen the exchange of information between production employees, gain better real-time visibility into the performance of its machinery, and make significant progress toward its vision of a connected factory.