Manufacturing simulation

Before introducing a new machine, automating an area, or expanding your plant, put your ideas to the test!

With advanced simulation, Merkur enables you to assess, validate, and visualize the impacts of your decisions before taking action. Explore multiple scenarios, identify bottlenecks, and optimize your flows to maximize your investments.

OUR EXPERTISE

Optimized manufacturing projects through 4D simulation

Optimized manufacturing projects through 4D simulation

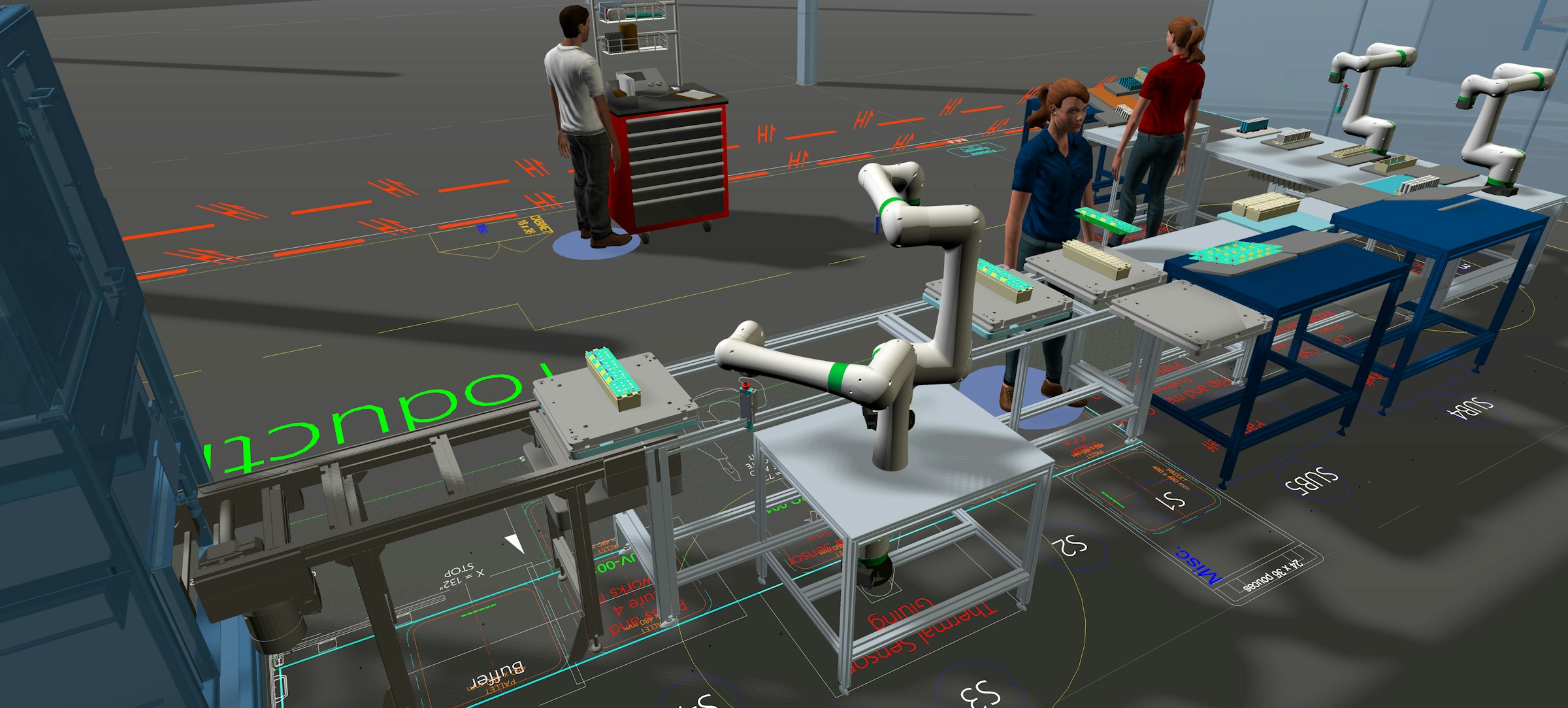

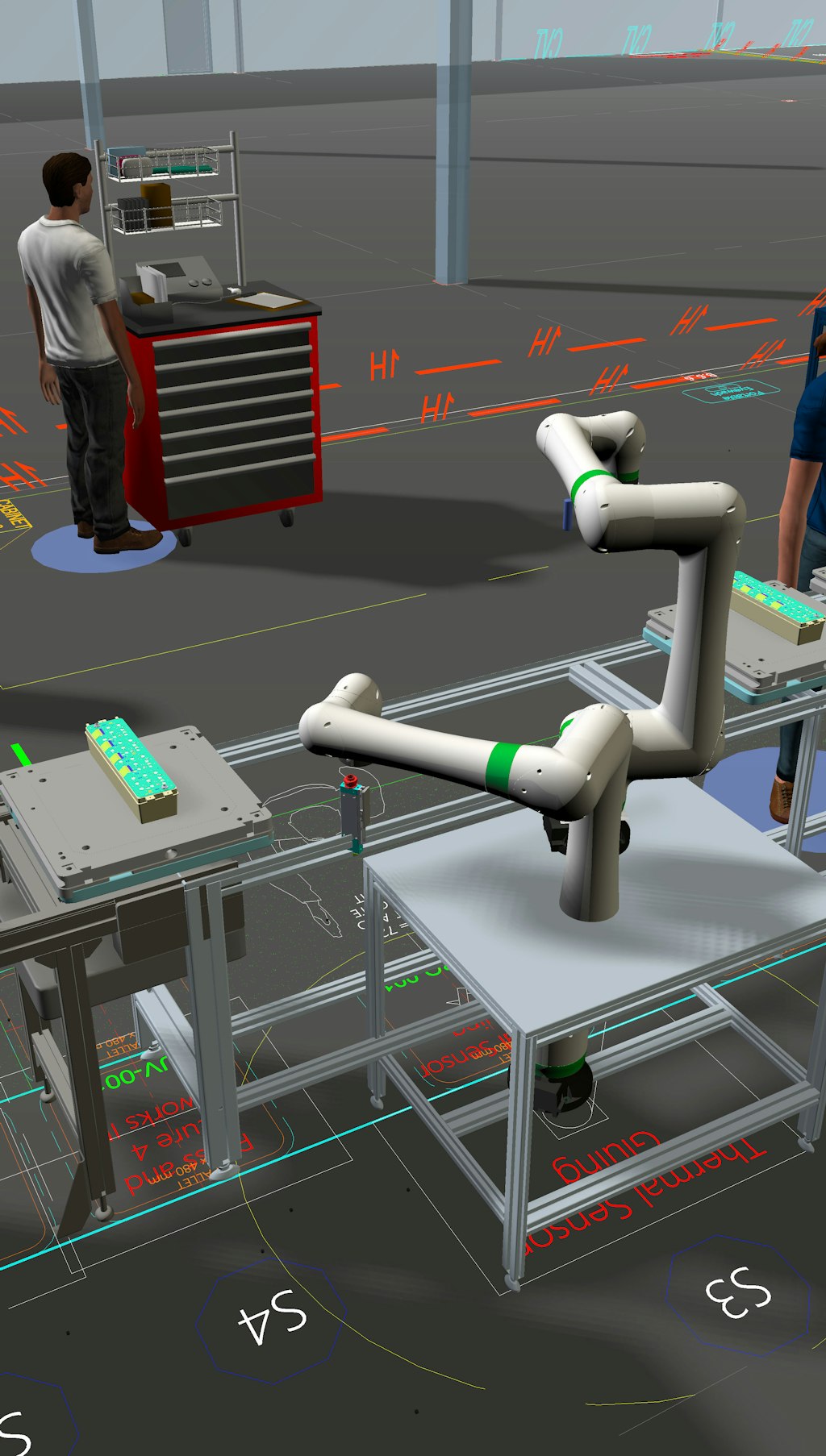

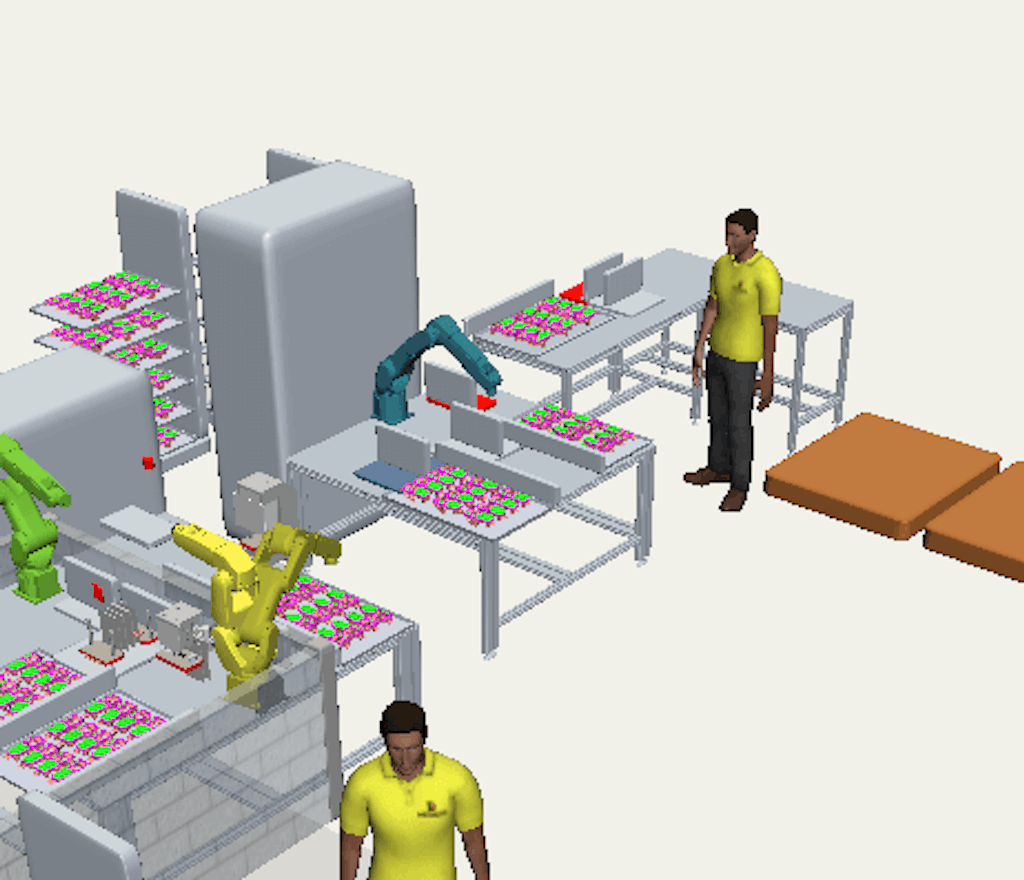

We harness the power of digital simulation to support your strategic decisions. Using 4D modeling and tools such as FlexSim, we help you assess realistic scenarios, choose the best strategies, and maximize the return on your investments. Our support covers the full life cycle of a manufacturing project.

- Plan your production capacity by simulating different scenarios

- Visually simulate the layout of work cells, assembly stations, and entire plants

- Validate your automation strategies before investing

- Analyze batch management and your product mix, and anticipate bottlenecks

- Optimize your logistics flows and warehouse organization (AGVs, tugger trains, conveyors, buffer zones)

- Diagnose the efficiency of your production lines

- Create a digital twin and emulate your robotic systems

- Secure your investments

Tools

FlexSim

Autodesk Revit

Omniverse

SolidWorks

Catia V5/V6

NX

Inventor

Our collaborative, multidisciplinary approach turns the complexity of your projects into clear, measurable decisions.

A clear, measurable view of your operations

Our experts model your manufacturing systems in 4D to align your projects with your strategic objectives and operational realities. You gain a realistic understanding of your plant’s performance and the impact of every proposed change.

Seasoned experts and powerful tools

FlexSim and our senior specialists allow you to precisely simulate your operations, logistics flows, and layout scenarios. You get a faithful representation of your industrial environment to anticipate challenges and reduce the risks tied to your investments.

Informed decisions, higher-performing projects

Our detailed simulations support decision-making, optimize planning, and reduce implementation costs. The result: projects that are more focused, better prepared, and better executed.

PROJECTS

Automation Strategy for a New Production Line

Manufacturing

Merkur worked with its client, an electronic components manufacturer, to implement an automation strategy for its new production line by deploying an operations simulation using FlexSim®.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.

ARTICLES

How Merkur Maximizes the Value of Your Investments in Automation Projects

Are you considering an automation project but lack the expertise or resources to take action?

The Essential Benefits of Robotic Simulation for your Project

4D at your Expansion Projects’ Service

You’re ready to expand or redesign your plant to support future growth, but you’re wondering how to go about it efficiently? Would you like to mobilize your teams around this strategic project for your company? Are you wondering about the right tools to support your communication during this change with tools that confirm your production strategy?