Manufacturing strategy and plant layout

Plan, design, and deploy high-performing, scalable manufacturing environments. We align your operations with your business objectives to accelerate growth and strengthen competitiveness.

OUR EXPERTISE

Custom strategies and layouts aligned with your business goals.

Custom strategies and layouts aligned with your business goals.

We help industrial companies plan and deliver their manufacturing transformation projects. Whether you are expanding a plant, implementing a new production line, or optimizing an operational network, every decision is guided by your objectives, your products, and your capabilities.

Through on-site analysis, 3D modeling, and technical expertise, we support you from the initial diagnosis to operations start-up. Our teams work hand in hand with yours to design high-performing, scalable, value-creating manufacturing environments—today and for the future.

- Assess your facilities’ capacity and space requirements

- Define the optimal manufacturing network for your operations

- Design your value chains and production flows

- Plan your overall plant layout

- Simulate and model implementation scenarios in 3D

- Receive support in selecting equipment

- Ensure rigorous project management during implementation

- Develop your industrial master plan

Tools

360° industrial assessment

Value Stream Mapping (VSM)

Industrial master plan

Capacity scenario modeling

Layout simulation (2D/3D)

Make-or-buy analysis

Flow and process analysis

Equipment and technology assessment

Our experts manage your industrial projects in an integrated way—from strategic framing to on-site execution—to turn your vision into tangible performance.

Optimize capacity and invest in growth

Design high-performing manufacturing sites aligned with your business objectives, products, and markets to support long-term growth.

Experts in strategy, engineering, and implementation

Our multidisciplinary teams combine their expertise to build practical, viable, and sustainable solutions tailored to your operating realities.

From concept to an operational plant

From strategic analysis to final layout, Merkur leads every stage of your industrial project to deliver efficient, scalable environments ready for the future.

PROJECTS

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

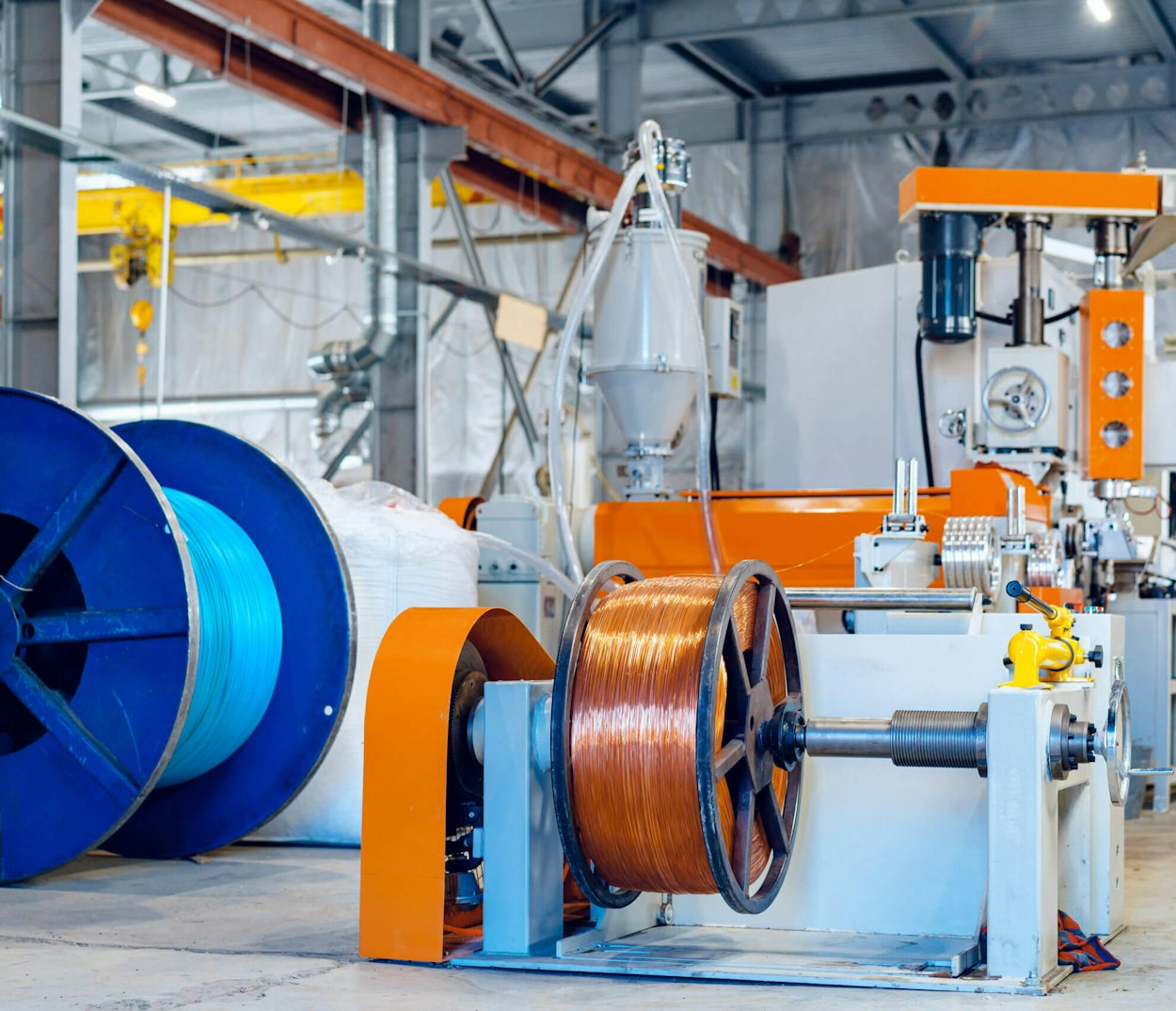

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.

ARTICLES

H55 Calls on Merkur for New Plant in Quebec

Discover how innovation and electrification are redefining aviation through the strategic collaboration between H55 and Merkur.

4D at your Expansion Projects’ Service

You’re ready to expand or redesign your plant to support future growth, but you’re wondering how to go about it efficiently? Would you like to mobilize your teams around this strategic project for your company? Are you wondering about the right tools to support your communication during this change with tools that confirm your production strategy?

Simultaneous Engineering : Decide Quickly, Deliver Well - Integrate Product, Process, and Infrastructure from the Start

What if your next infrastructure project had to move forward… without all the answers in hand?