Our Approach to Operational Systems Management

01 /04

We analyze your processes and systems to establish a rigorous diagnosis and define a clear, shared vision of the target state.

- Define strategic objectives

- Facilitate collaborative workshops

- Map processes and information flows

- Clarify the digital and operational vision

02 /04

We design the target architecture and select the technological and organizational solutions best suited to your context, priorities, and ambitions.

- Define the digital architecture

- Structure requirements specifications

- Select vendors and partners

- Engage key stakeholders

- Build a tailored roadmap

- Prioritize high-impact initiatives

03 /04

We turn vision into concrete actions through a progressive, secure, and well-coordinated implementation. We ensure project governance, team alignment, and change management to deliver sustainable results.

- Deploy the project management plan

- Launch pilot projects

- Monitor performance and KPIs

- Ensure deliverable control

- Adjust execution continuously

- Transfer knowledge

- Support change management

04 /04

We optimize your systems and fully leverage your data to maximize value creation, improve performance, and embed continuous improvement.

- Support operational ramp-up

- Monitor and analyze performance

- Optimize deployed solutions

- Embed continuous improvement

- Leverage data and information

- Update the target vision

Our services at the core of the integrated solution

Strategically grouped, our services ensure consistent and efficient management of your projects. This integration fosters innovation, reduces risks, and optimizes results at every stage.

Digital project management

From strategy to execution: PMO, vendor selection, rollout plan and adoption for successful go lives.

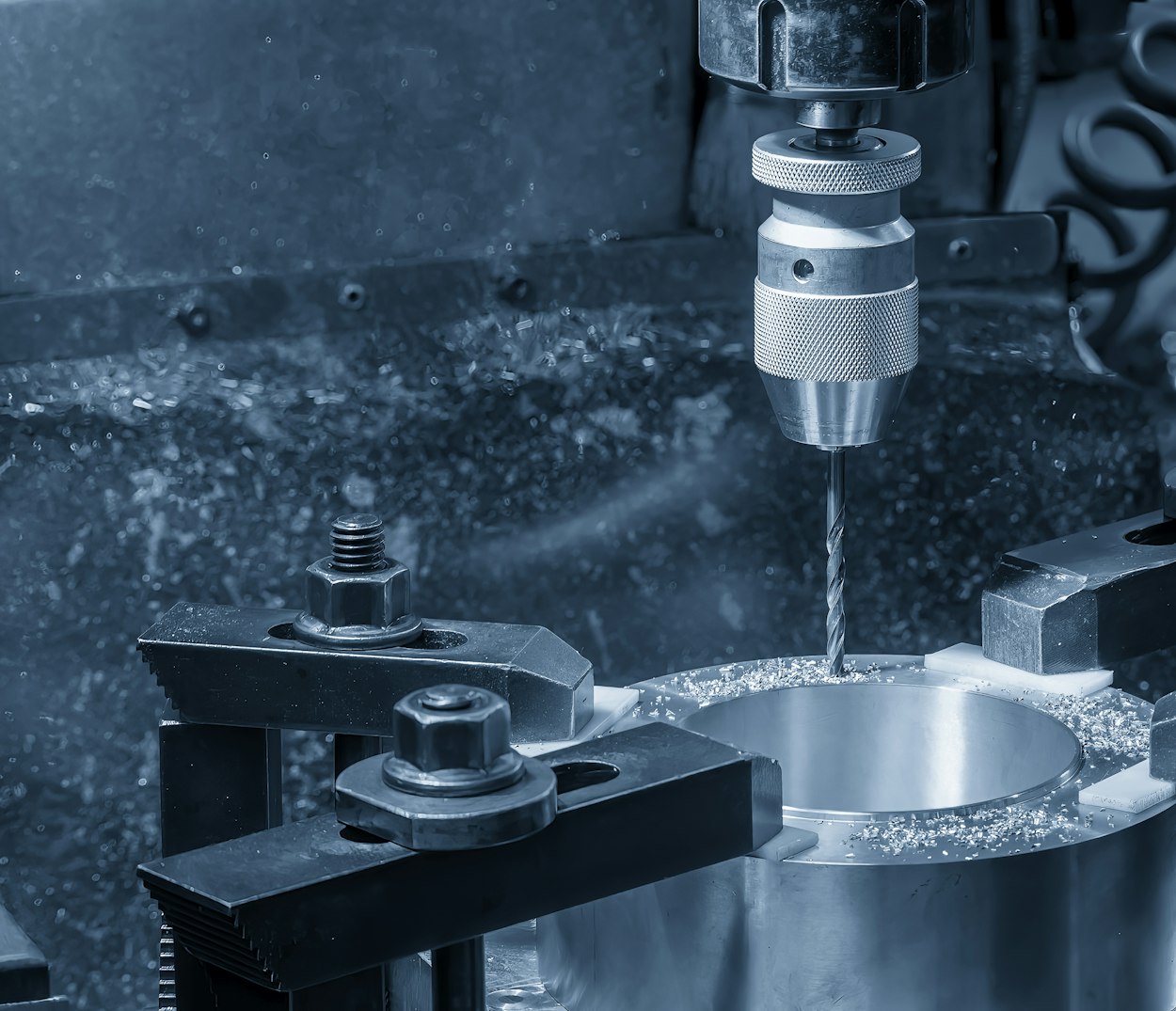

Operational Process Optimization

Transform your processes with a data driven, Lean approach: mapping, digital and operational diagnostics, automation, KPIs, and deployment support.

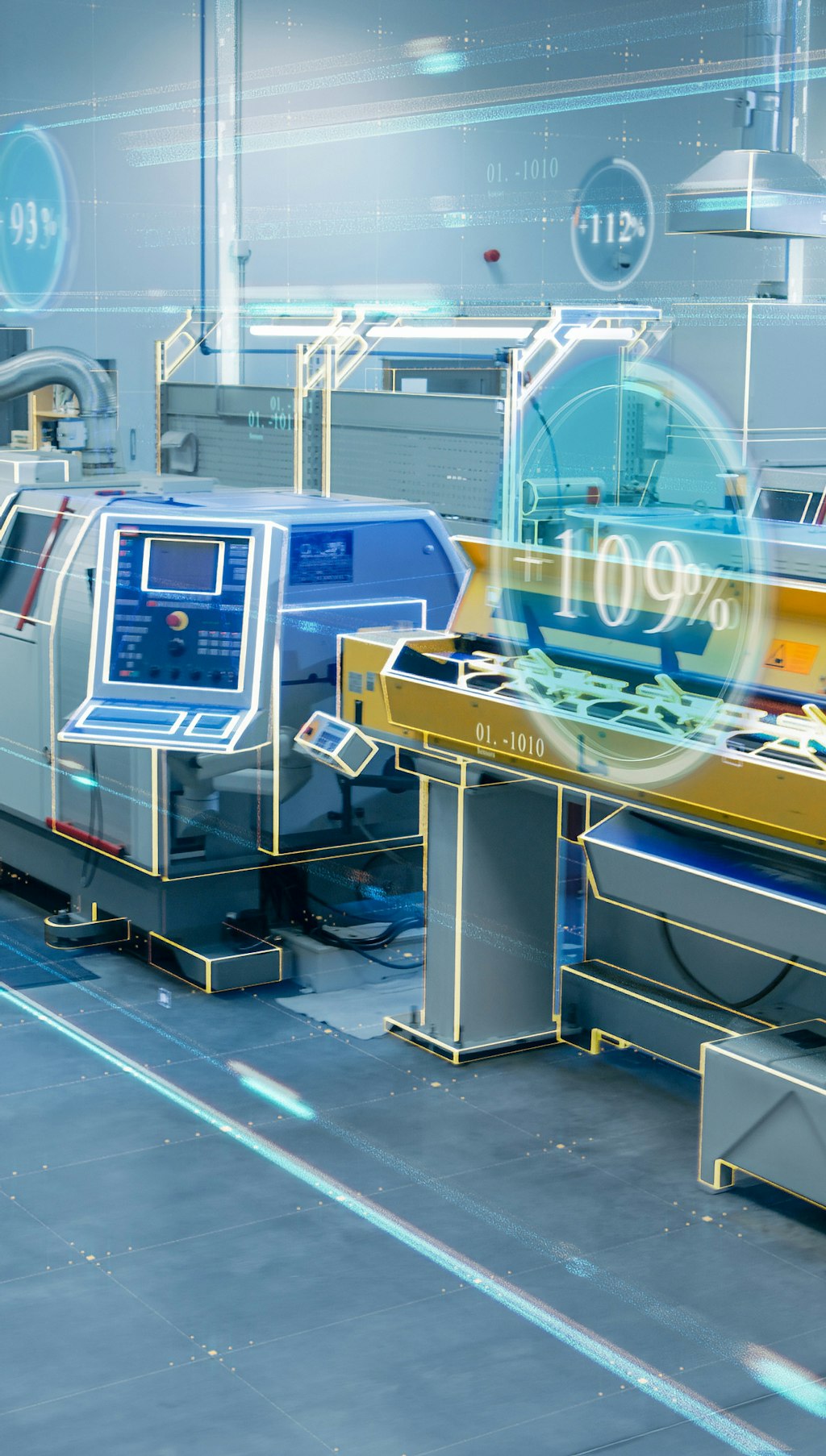

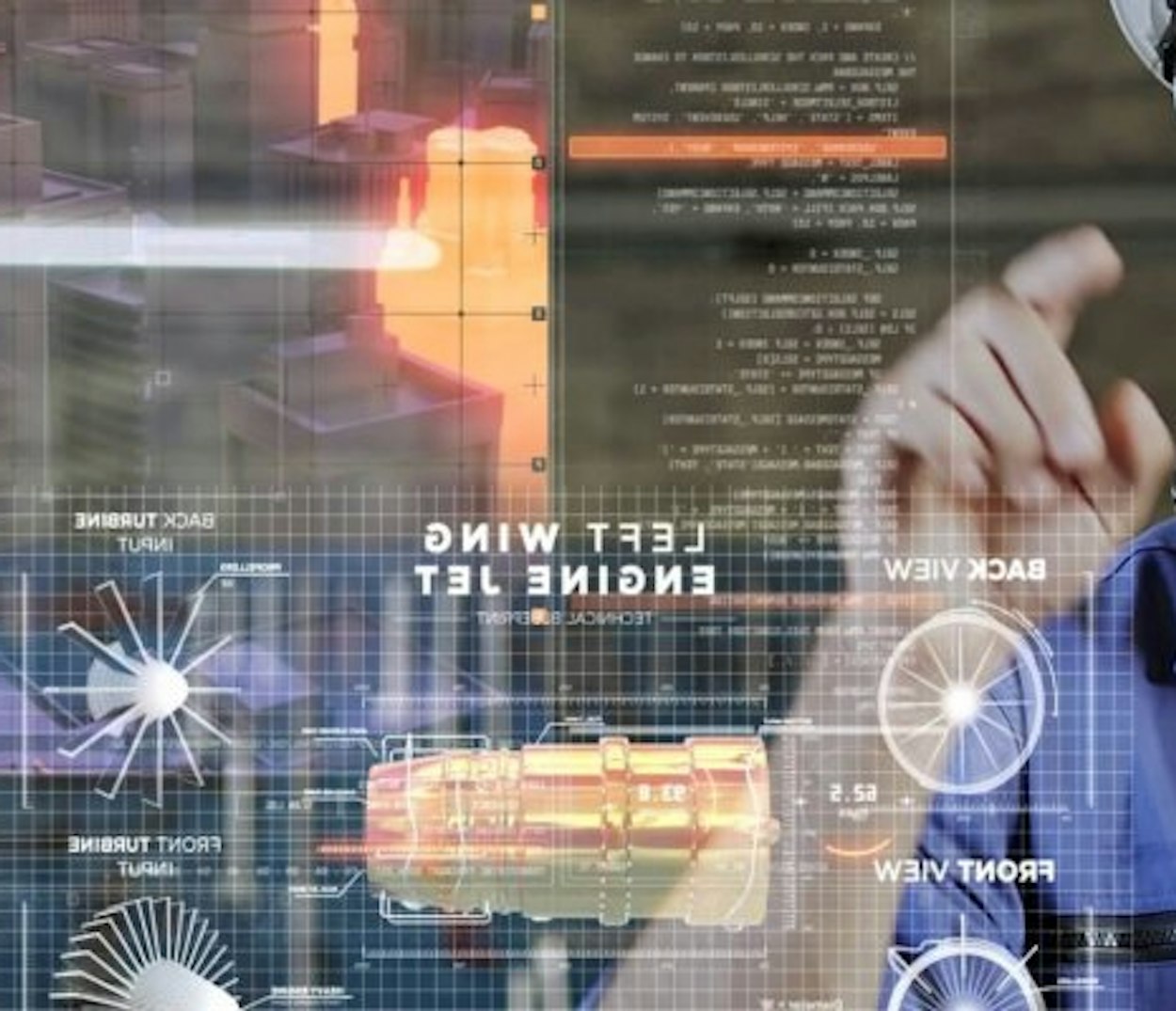

Digital Transformation

From strategy to execution: architecture, connectivity and line of business solutions (ERP, MES/SCADA, WMS, IIoT, BI/AI) to accelerate performance.

Business Intelligence and AI

From data to action: warehouse, dashboards and AI to anticipate, decide faster and build durable competitive advantage.

PROJECTS

Lemay Outillage Successfully Turns Digital

Manufacturing

Lemay Outillage specializes in supporting the design and manufacture of tooling. The company was seeking to strengthen the exchange of information between production employees, gain better real-time visibility into the performance of its machinery, and make significant progress toward its vision of a connected factory.

Standardizing Production Through Digital Transformation

Manufacturing

Our client, Canam Group, specializes in the design and manufacture of metal components for the construction industry in North America. With the acquisition of three plants, Canam Group wanted to find a solution to remotely monitor the status of its machinery in order to implement production improvements.

ARTICLES

Improve the Performance of your Metal Processing Plant with Digital Technologies

Metal transformation plants must think of new solutions to manage their operations and improve their performance

Strategies to Optimize Communication and Collaboration in Your Operations

In your daily operations, you may be responsible for coordinating production activities and ensuring that your colleagues work well together to transform strategic objectives into concrete actions.

The Winning Combination of Operational Excellence and Intelligent Factory

The combination of operational excellence and smart factory can help companies improve their competitiveness in a constantly changing market.