Improve the efficiency and profitability of your operations

Every operation demands rigor and agility. We bring tailored, multidisciplinary expertise to optimize your processes, accelerate ramp-up, and ensure compliance. Our approach integrates project management, automation, operational excellence, and digital transformation to support performance optimization and your company’s growth.

Optimize innovation and accelerate time-to-market

Dans un secteur où performance et innovation dictent la compétitivité, nous concevons, validons et industrialisons des systèmes complexes conformes aux normes aéronautiques. Notre approche structurée stimule la créativité et la collaboration, intègre la simulation numérique pour réduire les risques et optimise la fabrication et la rentabilité de vos produits.

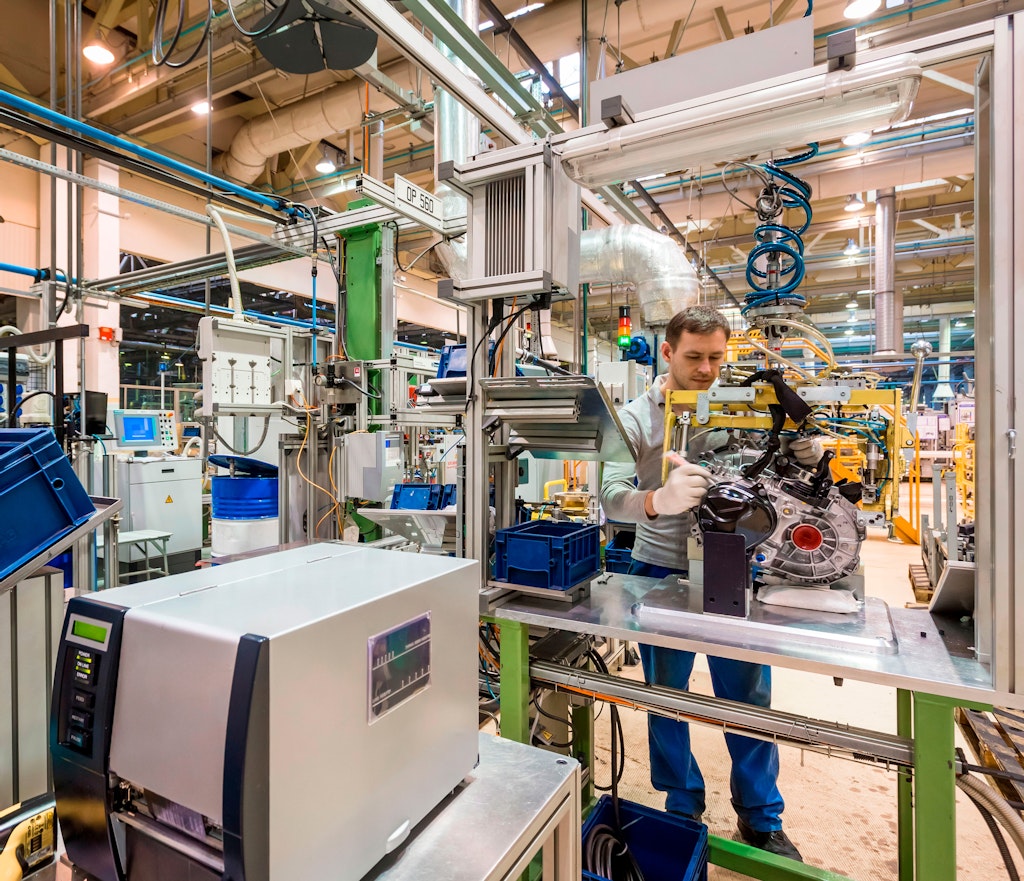

End-to-end mastery of the aerospace development cycle

We combine advanced digital tools, proven engineering, and deep sector expertise to secure every stage of the aerospace development cycle. From design to production, we ensure performance, compliance, and risk reduction by integrating the industry’s best practices and technologies.

OUR SERVICES

Solutions tailored to aerospace industry

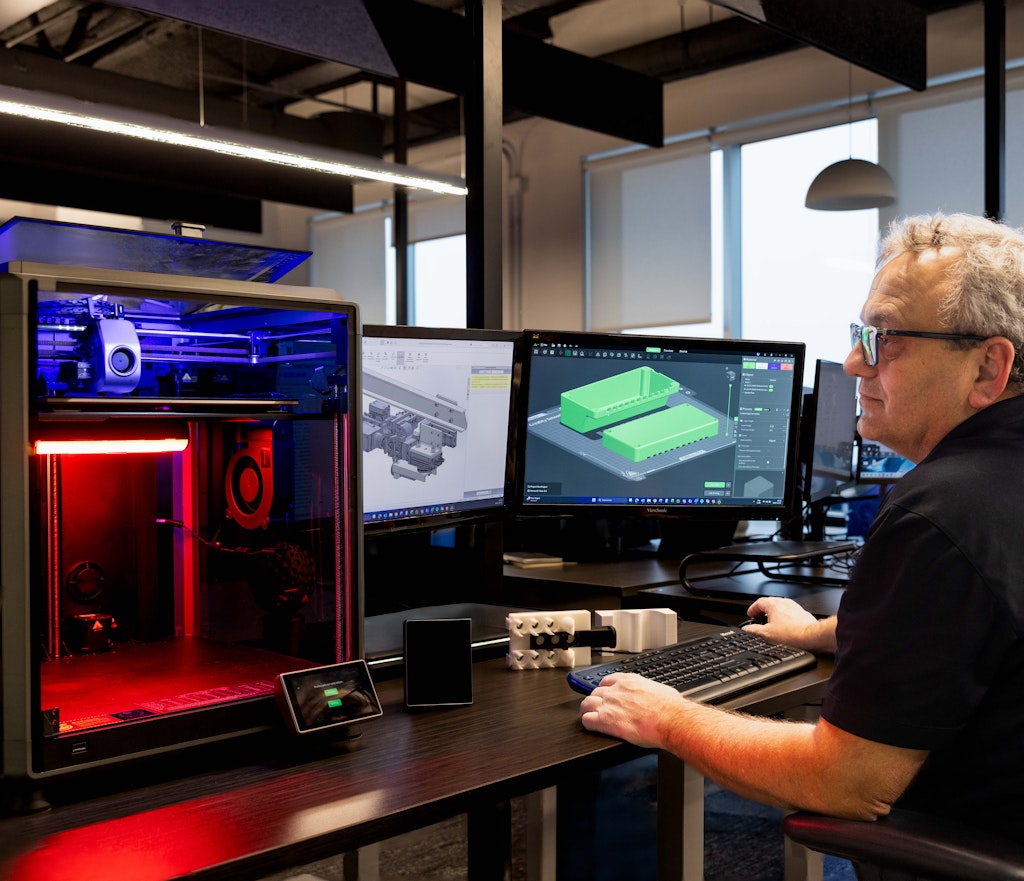

Mechanical Engineering and Product Design

Design, simulation, and validation to confidently industrialize your products.

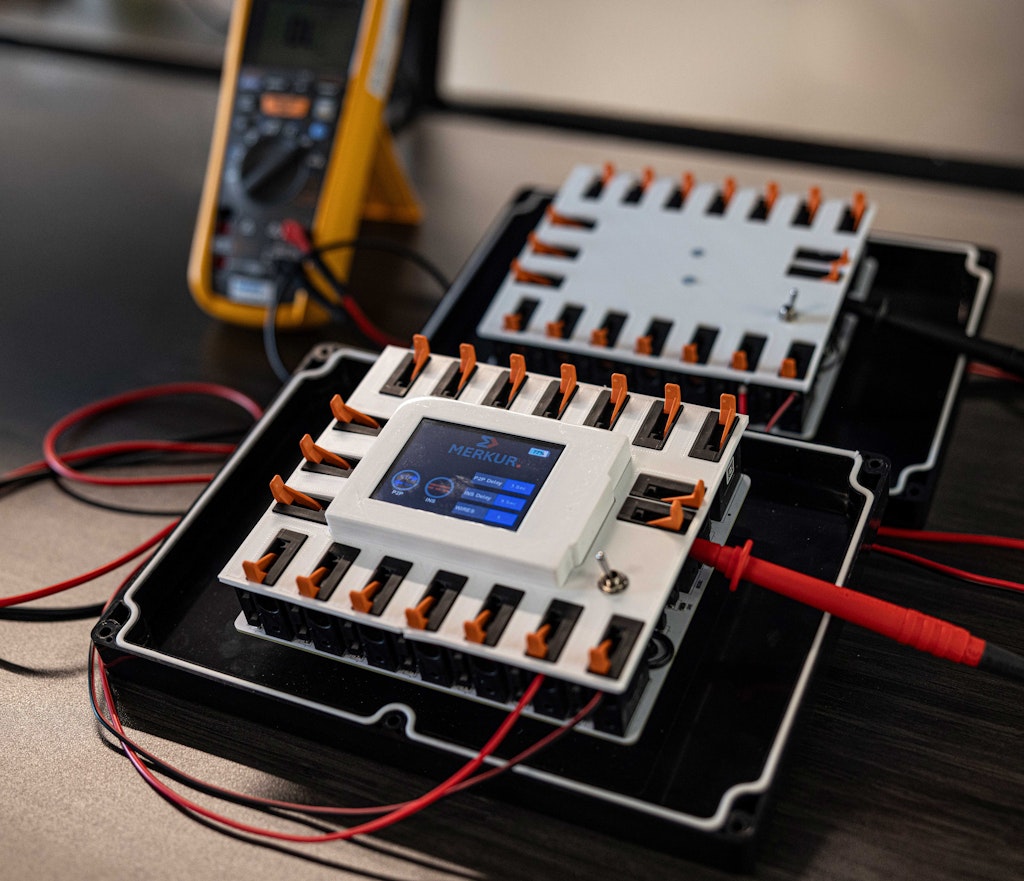

Electrical and Electronic Engineering

From requirements to production: electronic design, harnesses, panels, firmware and EMC validation.

Operational diagnostic

A field led operational diagnostic revealing waste, bottlenecks and opportunities. Concrete, ROI prioritized recommendations to improve performance sustainably.

Lean Manufacturing

A Lean program tailored to your plant: on site diagnostic, collaborative workshops and a prioritized action plan to remove waste, stabilize processes and lift performance for the long run.

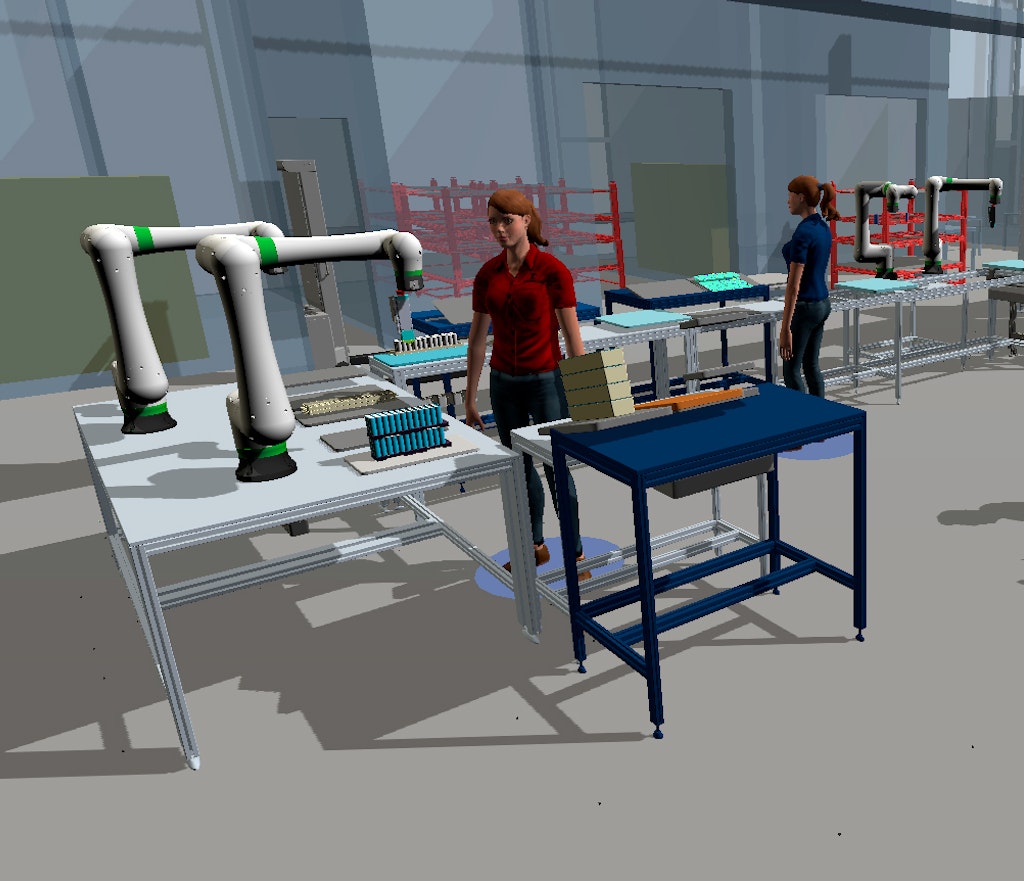

Manufacturing Simulation

Before automating, reconfiguring, or expanding, simulate your operations in 4D. Visualize impacts, eliminate bottlenecks, and maximize ROI.

Expansion and implementation of facilities

Your partner to plan, coordinate and deliver plant expansions or greenfield factories: project management, facility layout, commissioning and startup support.

Digital project management

From strategy to execution: PMO, vendor selection, rollout plan and adoption for successful go lives.

Tooling and Equipment Design

From requirements to commissioning: Merkur designs and integrates industrial tooling and equipment (mechanical, hydraulic, pneumatic, electrical, automation) to make operations safer and more productive.

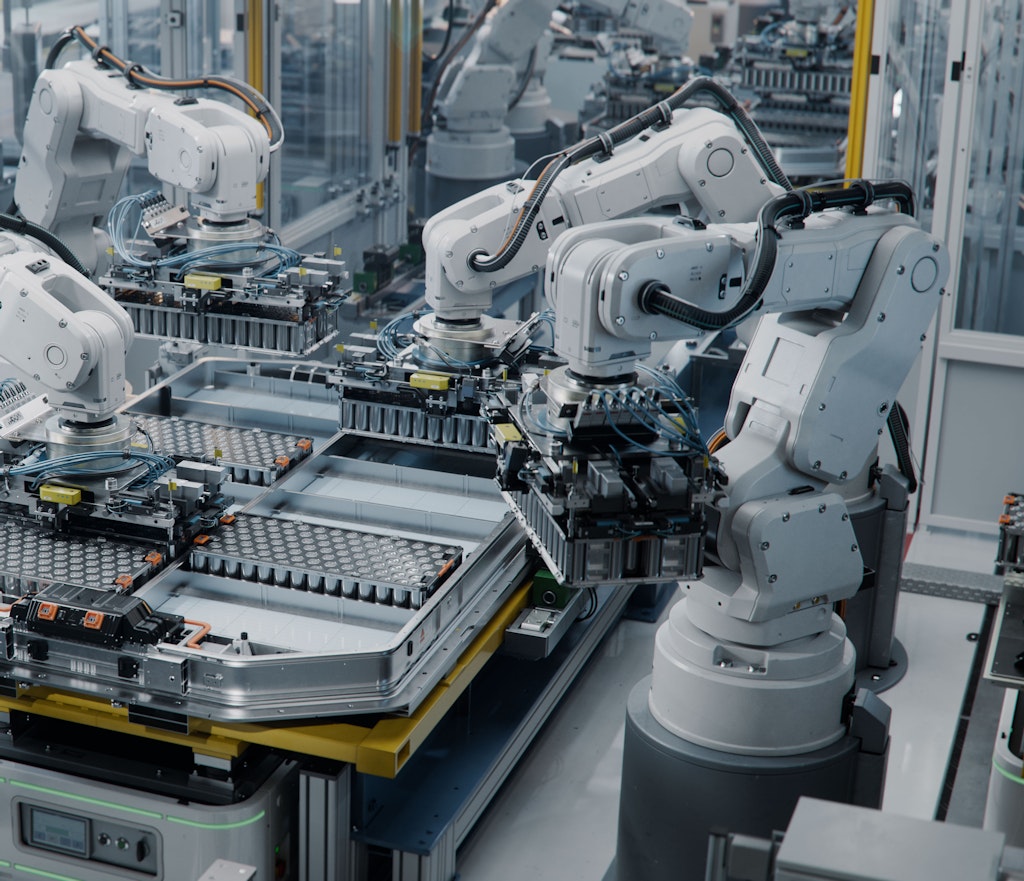

Industrial Automation and Robotics

Discover how Merkur designs and delivers automation and robotics solutions to optimize your processes and accelerate industrial transformation.

OUR CUSTOMERS

They trust us to drive their innovation and performance.

PROJECTS

Turnkey Delivery of a Tool Transport Cart

Aerospace

Merkur worked with one of its customers in aircraft manufacturing to optimize assembly operations. We applied 5S principles to the design of a new cart meeting health and safety standards.

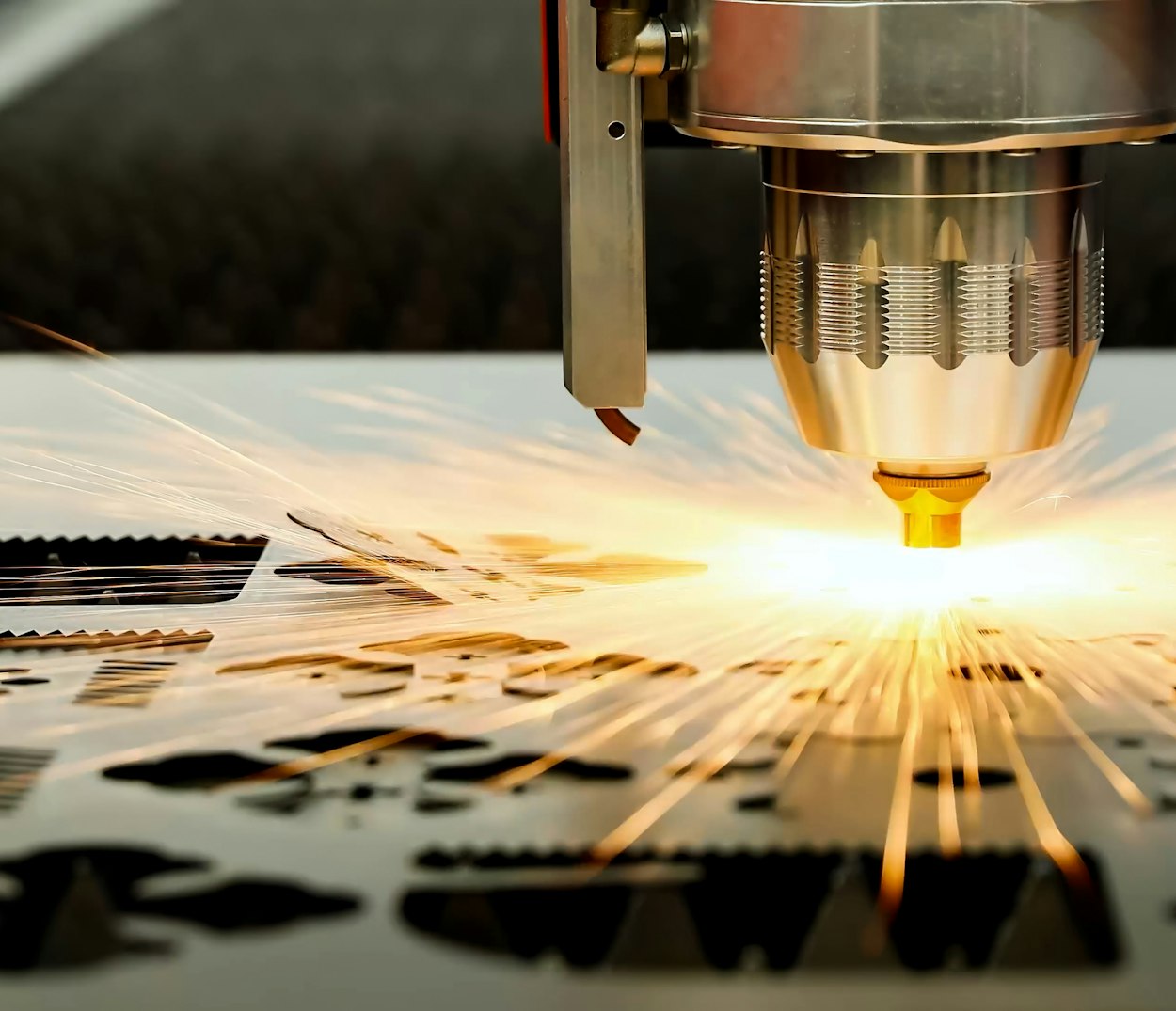

A successful digital transition for Metalus’s new smart factory

Manufacturing

Metalus specializes in sheet metal fabrication. The company, which has seen steady growth since 1988, found itself at an impasse created by a logistics problem: its 125 employees were having to manually distribute more than 1000 work orders a week.

ARTICLES

How can Merkur help you with your mechanical design tooling projects?

In this article, Merkur's Director of Product Development explains why conceptual design is essential to the success of your product development project...

Strategies to Optimize Communication and Collaboration in Your Operations

In your daily operations, you may be responsible for coordinating production activities and ensuring that your colleagues work well together to transform strategic objectives into concrete actions.

Simultaneous Engineering and DFMA Integration: Crucial Elements in the Product Development Process

In the complex world of product design, certain approaches stand out, such as DFMA (Design for Manufacturing and Assembly), which enables products to be designed in such a way as to make them easier and less costly to produce and assemble. When integrated with simultaneous engineering, DFMA brings many advantages, which we will explore in this article.