Meet the unique challenges of your market

We turn the energy transition into a growth driver. Merkur supports you in designing, validating, and industrializing high-performance electrified systems, while reducing technical, regulatory, and operational risks. Our solutions span project management, industrialization, digital transformation, and supply-chain security to ensure performance and compliance.

From design to compliance, without compromise

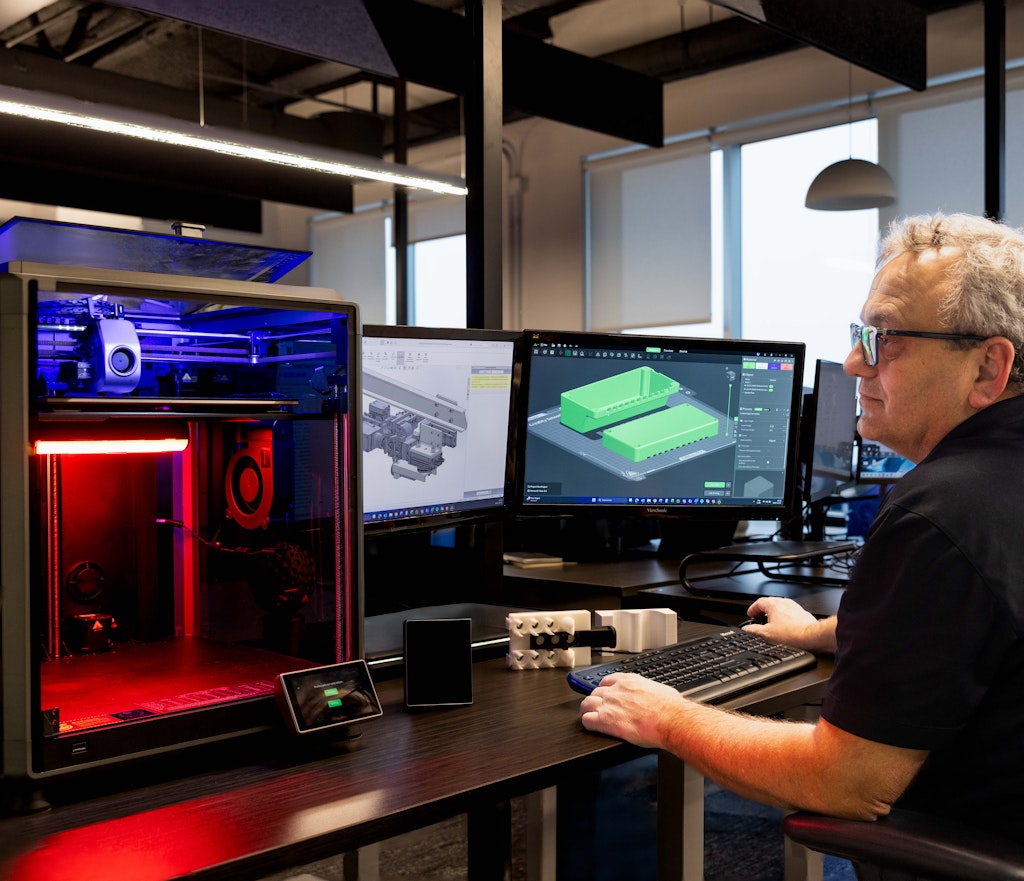

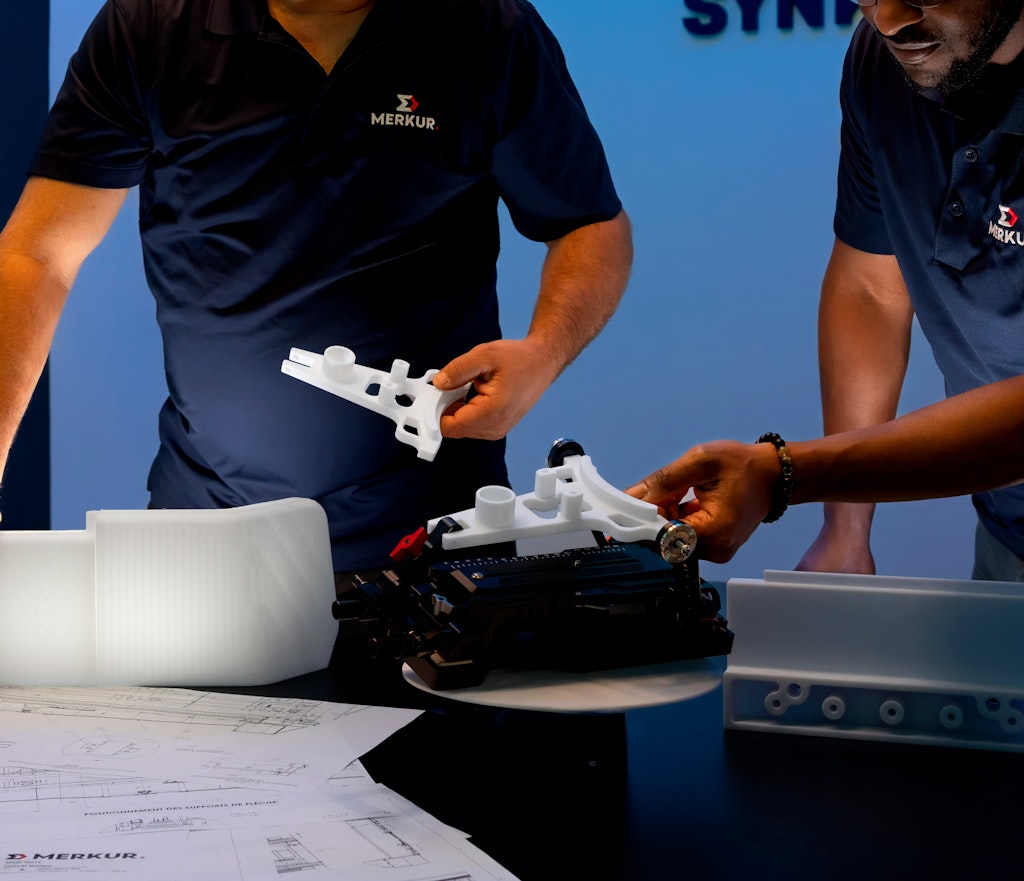

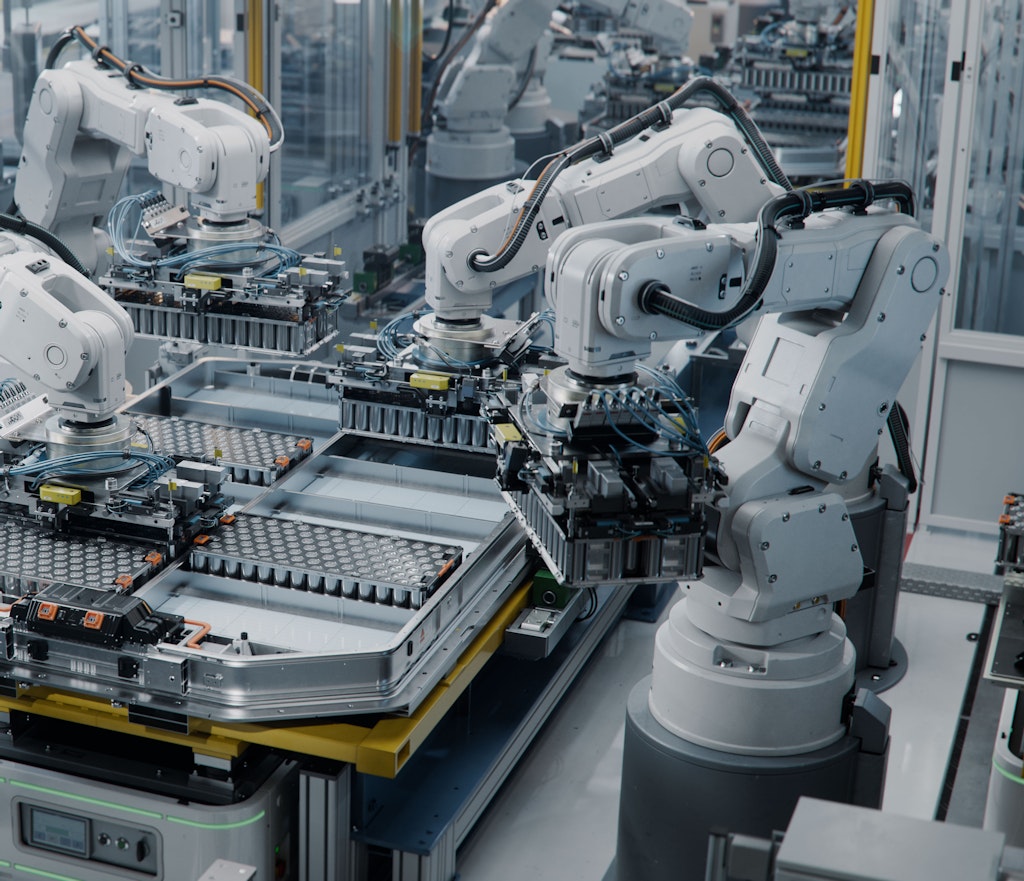

To deliver successful electrification, we draw on systems engineering, advanced simulation, rigorous validation, and manufacturing industrialization. We master electrical, electronic, and mechanical design, while integrating quality, safety, process optimization, and sustainability. Our expertise includes system validation, automation, and the design of specialized tooling to ensure performance and reliability.

A complete lifecycle to de-risk your electrification projects

To accelerate industrialization and reduce risk, we deploy advanced digital tools and proven methods across the entire lifecycle: design, validation, industrialization, real-time monitoring, and energy optimization. With integrated platforms and connected solutions, we deliver the precision, reliability, and performance needed to bring your electrification projects to life.

OUR SERVICES

Solutions tailored to electrification

Product Development Project Management

We manage your projects with clear governance, agile practices, and KPIs that secure quality, cost, and schedule.

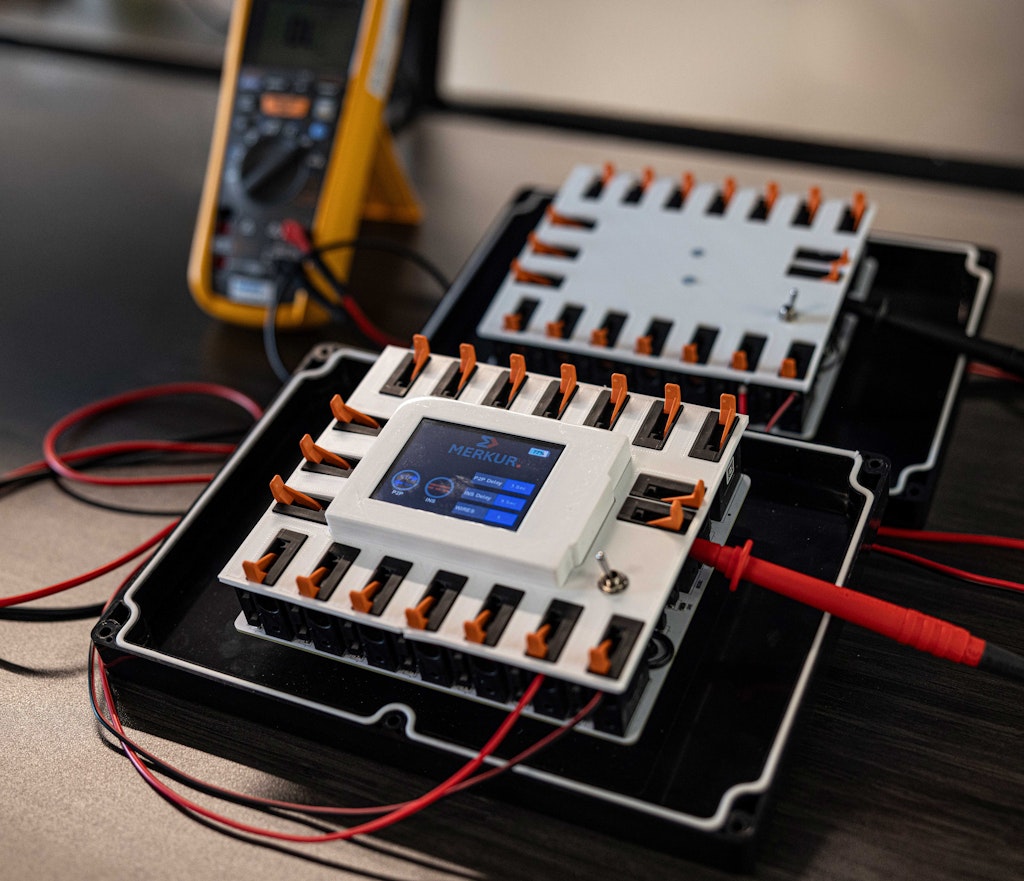

Electrical and Electronic Engineering

From requirements to production: electronic design, harnesses, panels, firmware and EMC validation.

Mechanical Engineering and Product Design

Design, simulation, and validation to confidently industrialize your products.

Product optimization

Analysis, redesign, and validation for more competitive, reliable, and manufacturable products.

Manufacturing Project Management

From strategy to operations: governance, risk, quality, EHS and performance for successful, measurable startups.

Digital project management

From strategy to execution: PMO, vendor selection, rollout plan and adoption for successful go lives.

Industrial Automation and Robotics

Discover how Merkur designs and delivers automation and robotics solutions to optimize your processes and accelerate industrial transformation.

Expansion and implementation of facilities

Your partner to plan, coordinate and deliver plant expansions or greenfield factories: project management, facility layout, commissioning and startup support.

Manufacturing Strategy and Plant Layout

From diagnosis to ramp up: network design, layout, capacity and equipment selection for sustainable gains.

OUR CUSTOMERS

Companies that trust us.

PROJECTS

Integration of an Electronic Module for Motorized Watercraft

Electrification

Merkur worked with one of its customers, a manufacturer of motorized watercraft and recreational vehicles, to modernize one of its pieces of equipment.

Industrial plant expansion project at LPM

Manufacturing

LPM is a company specialized in closed die-forging, stamped part production and production line integration. LPM had a potential for growth and investment in more efficient machines that no longer corresponded to the structure and space of the current building.

ARTICLES

Knowing your Market and your Customers: The Key to Successful Product Development!

Do you see opportunities for innovation and improvement that could benefit your company? Do you have a project in mind that you’d like to present? Make the most of the summer to get ready!

Take the Opportunity to Innovate

The word innovation is on everyone’s lips: the importance of innovating, of finding innovative solutions. Yes! But how? How can we do this, when day-to-day business often takes precedence over creative and strategic thinking?

Simultaneous Engineering and DFMA Integration: Crucial Elements in the Product Development Process

In the complex world of product design, certain approaches stand out, such as DFMA (Design for Manufacturing and Assembly), which enables products to be designed in such a way as to make them easier and less costly to produce and assemble. When integrated with simultaneous engineering, DFMA brings many advantages, which we will explore in this article.