Mining operations optimization

We support the expansion, optimization, and modernization of your mining sites at every stage: extraction, haulage, processing, and maintenance. Our robust, tailored solutions enable project management, team performance, automation, digital transformation, specialized equipment development, downtime reduction, and the qualification of strategic suppliers.

From operational challenge to lasting improvement

We create safer, more efficient environments aligned with on-the-ground realities. Working with your teams, we turn mining operational challenges into drivers of sustainable improvement: asset availability optimization, OHS risk analysis, tooling design, data digitalization and analytics, equipment modernisation, Lean initiatives, and co-development.

Equipped teams, streamlined operations

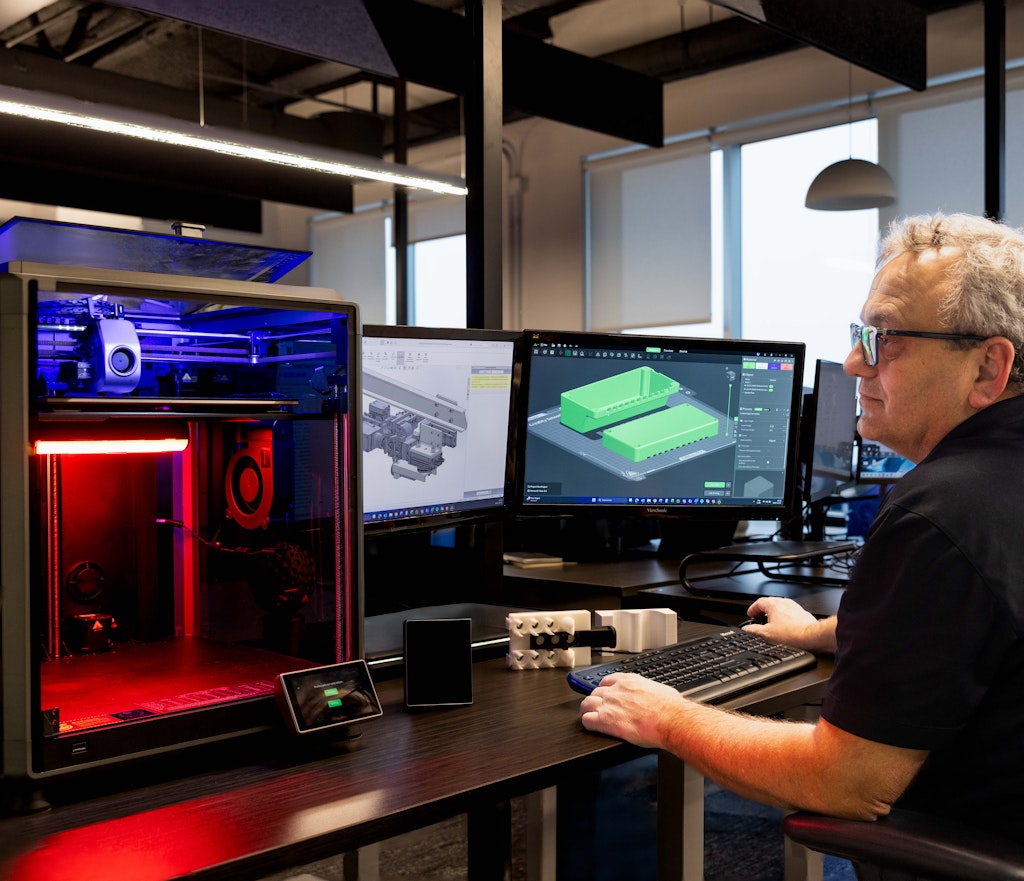

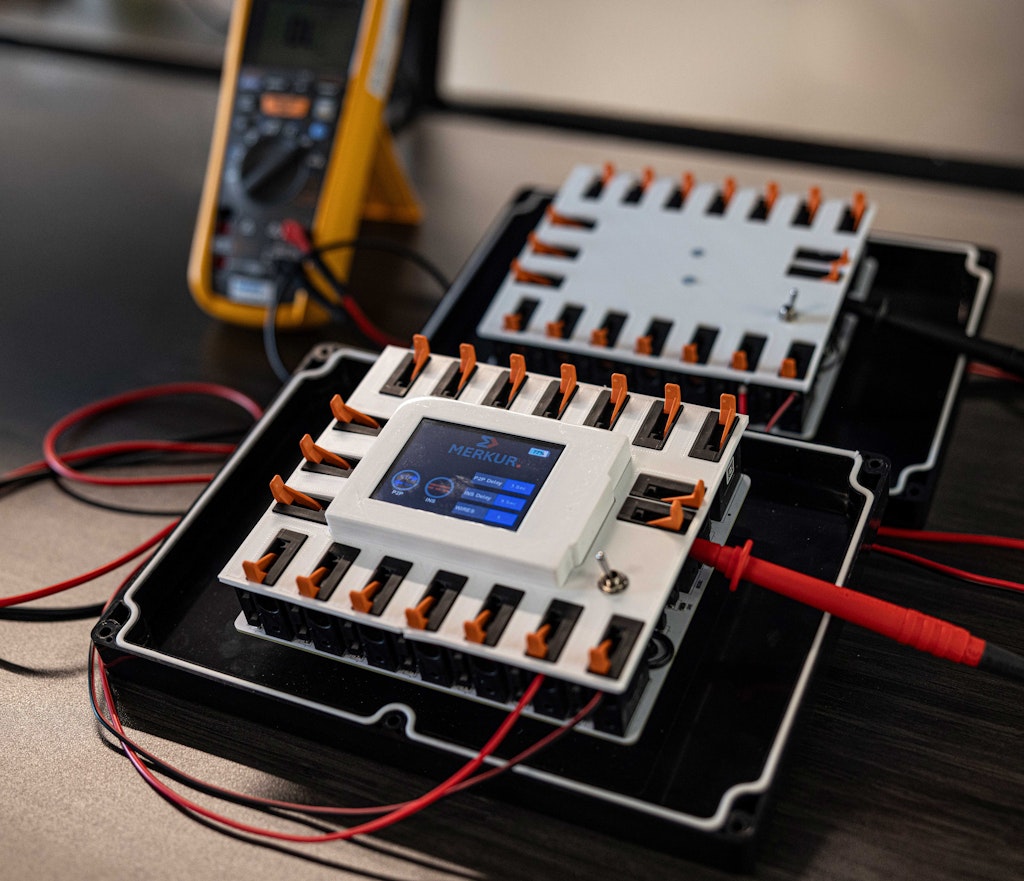

Merkur equips operators and OEMs for high-performing, connected mining operations: dashboards, advanced simulation, 3D modeling, real-time monitoring, value-added analysis, energy and ergonomic optimization, Lean methods, 3D design, and connected technologies. Our solutions streamline processes and maximize field efficiency.

OUR SERVICES

Solutions tailored to mining industry

Operational diagnostic

A field led operational diagnostic revealing waste, bottlenecks and opportunities. Concrete, ROI prioritized recommendations to improve performance sustainably.

Mechanical Engineering and Product Design

Design, simulation, and validation to confidently industrialize your products.

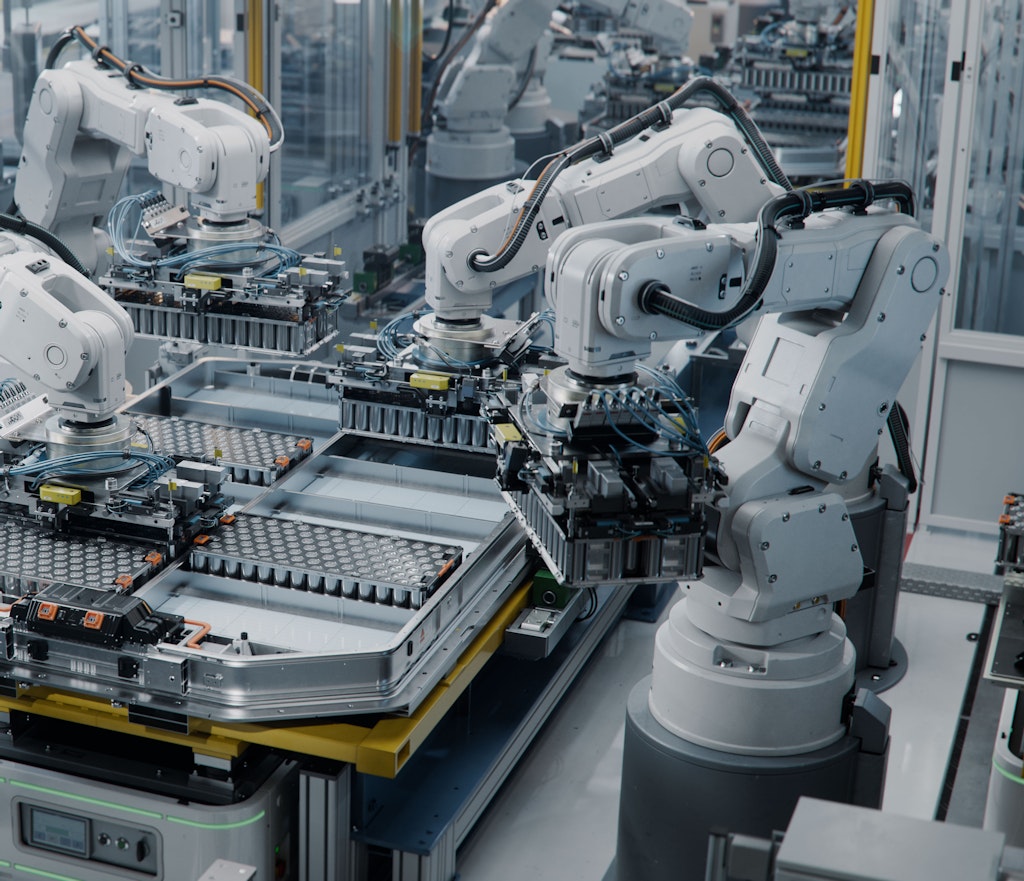

Industrial Automation and Robotics

Discover how Merkur designs and delivers automation and robotics solutions to optimize your processes and accelerate industrial transformation.

Supply Chain Strategy

S&OP, S2P, demand planning, inventory optimization, end-to-end visibility, control tower, APS, WMS, TMS, AI, supplier resilience.

Business Intelligence and AI

From data to action: warehouse, dashboards and AI to anticipate, decide faster and build durable competitive advantage.

Infrastructure and Building Services

From needs assessment to testing and commissioning: Merkur coordinates electrical power, compressed air, HVAC, process water and fire protection for seamless integration into plant operations.

Electrical and Electronic Engineering

From requirements to production: electronic design, harnesses, panels, firmware and EMC validation.

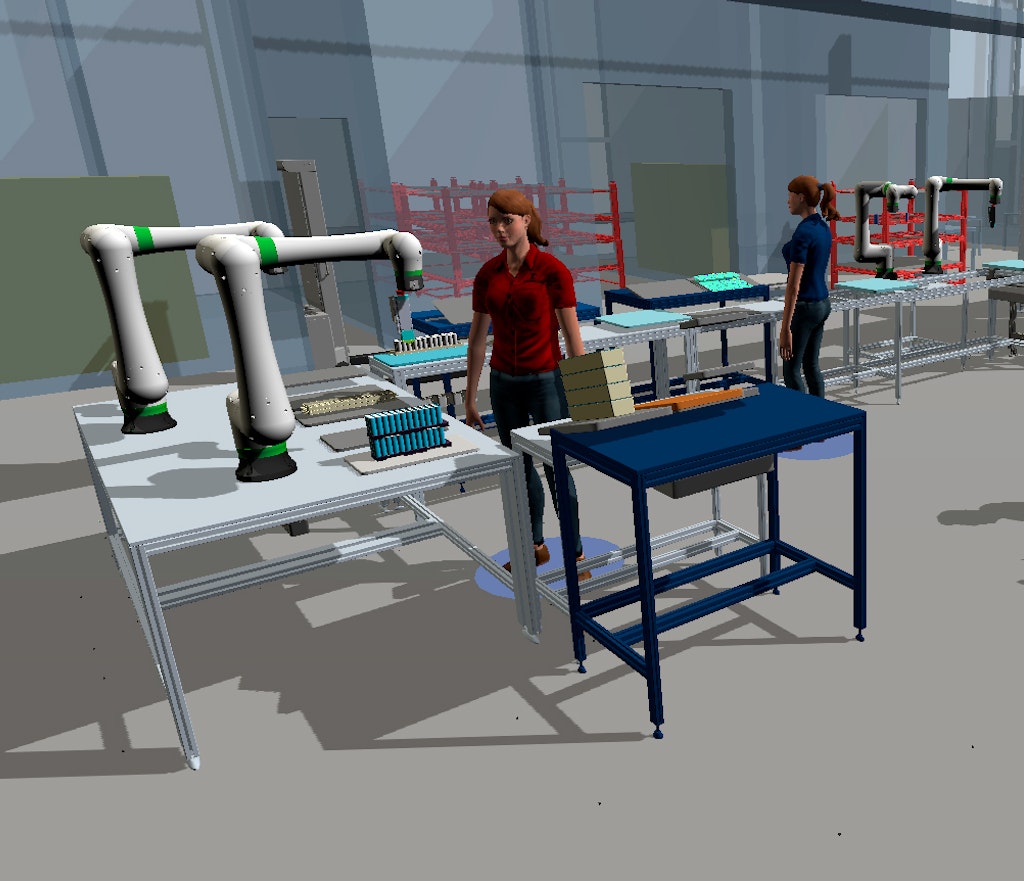

Manufacturing Simulation

Before automating, reconfiguring, or expanding, simulate your operations in 4D. Visualize impacts, eliminate bottlenecks, and maximize ROI.

Digital project management

From strategy to execution: PMO, vendor selection, rollout plan and adoption for successful go lives.

OUR CUSTOMERS

Companies that trust us.

PROJECTS

Automation Strategy for a New Production Line

Manufacturing

Merkur worked with its client, an electronic components manufacturer, to implement an automation strategy for its new production line by deploying an operations simulation using FlexSim®.

Numerical Simulation for the Company Pro Pac Industries

Manufacturing

Pro Pac Industries, a major company in the forestry domain, wanted to carry out a major upgrade of its product line. To meet their needs and obtain assistance in the design and improvement of various delimber head models, they called on Merkur’s numerical simulation experts.

ARTICLES

How Merkur Maximizes the Value of Your Investments in Automation Projects

Are you considering an automation project but lack the expertise or resources to take action?

Control and reduce your Manufacturing Costs with Lean

How can you increase productivity, shorten production lead times, lower inventory, and cut more than 50% of manufacturing errors and defects?

4D at your Expansion Projects’ Service

You’re ready to expand or redesign your plant to support future growth, but you’re wondering how to go about it efficiently? Would you like to mobilize your teams around this strategic project for your company? Are you wondering about the right tools to support your communication during this change with tools that confirm your production strategy?