Digital transformation made easy with the SYNKRO® connectivity solution

- Client

- Confidential

- Sector

- Manufacturing

- Expertise

- Operational Systems Management

CONTEXT

CHALLENGES

ASSIGNMENT

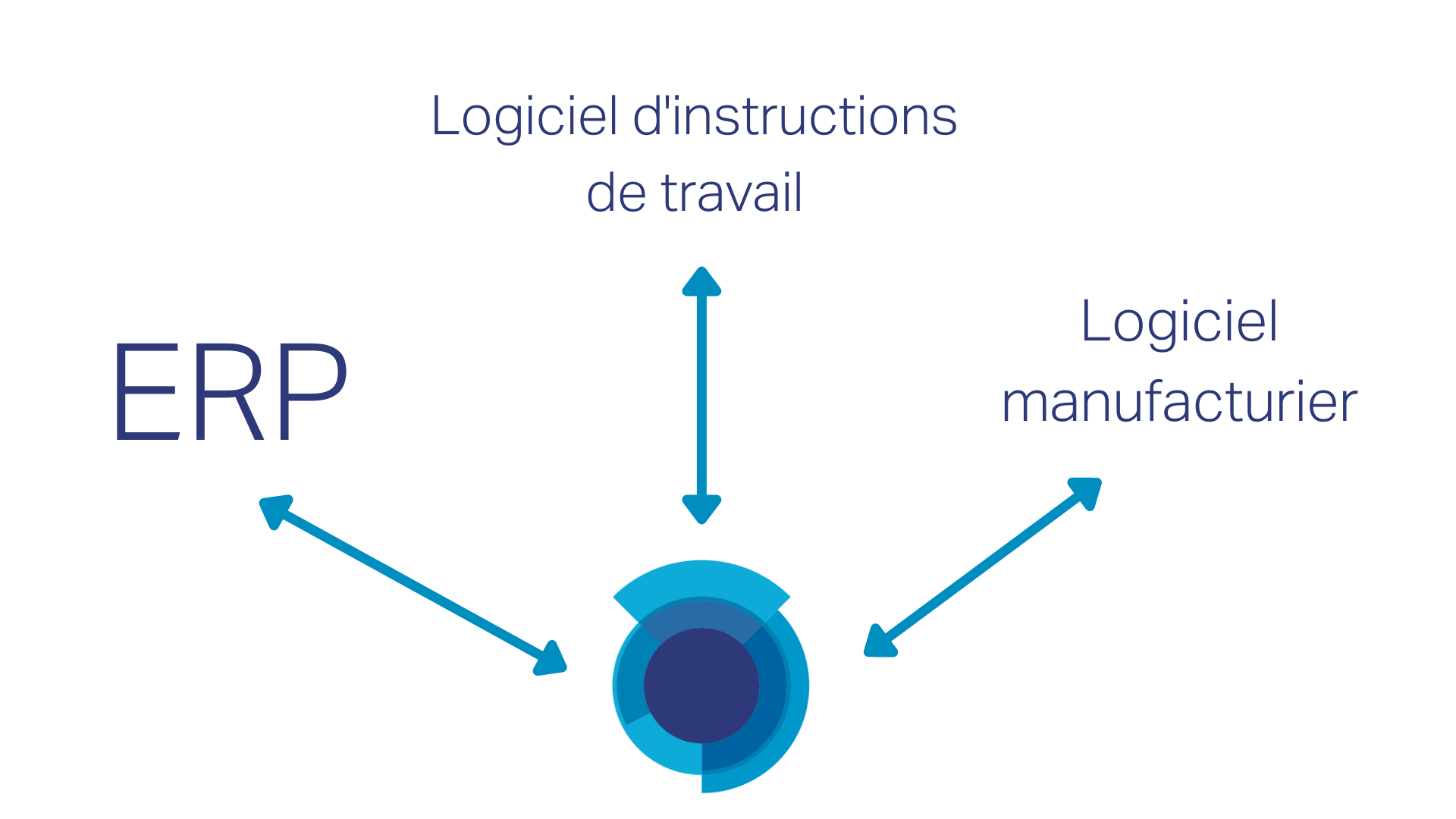

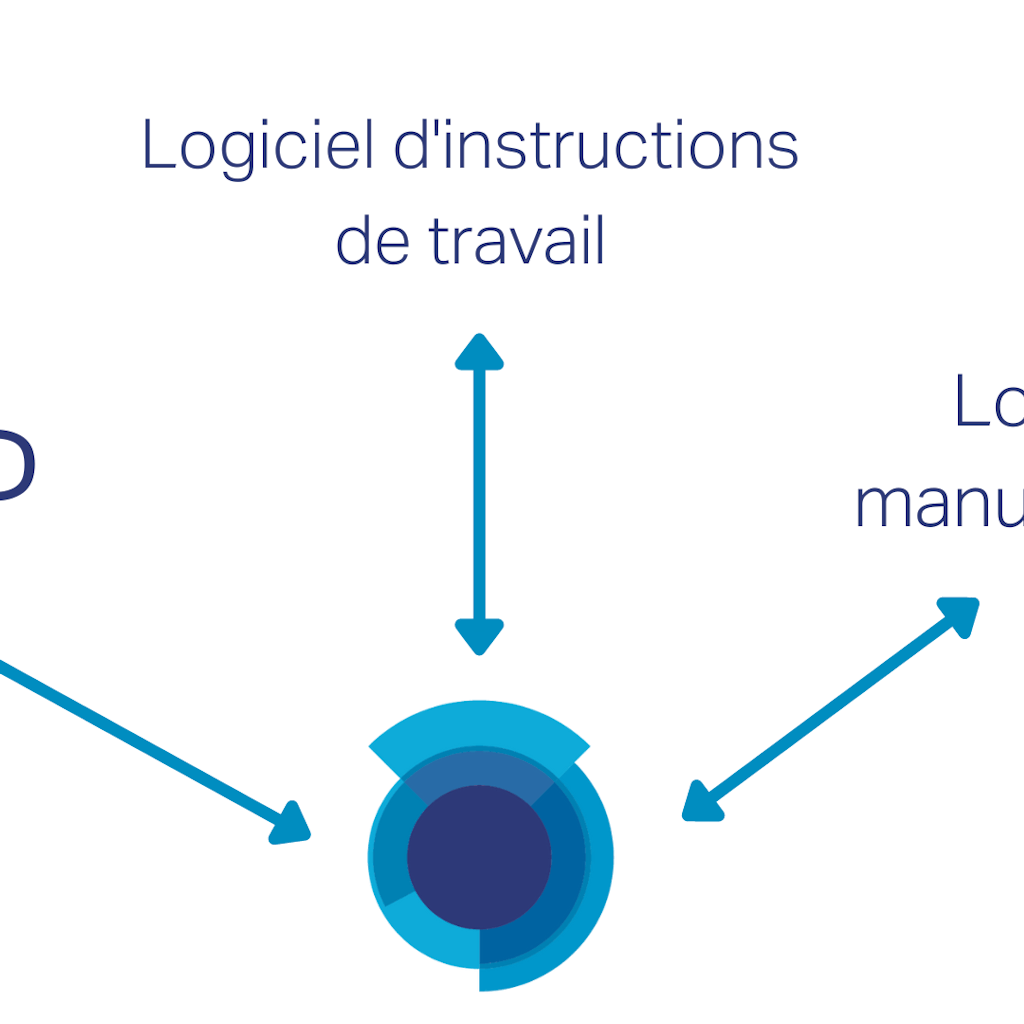

As our clients already had an ERP system (ProcessPro), a manufacturing data acquisition software (CapStone) and a work instructions software (VKS), Synkro team was tasked with building bridges between the different systems in order to route requests to the right system.

Instead of manually entering more than a hundred work orders into the software, SYNKRO automatically routes requests from the ERP to the work instruction system, eliminating the risk of errors associated with manual data transcription.

SYNKRO also reads selected machine sensors, validates laboratory results, and initiates material consumption — having first verified inventory levels in real time — all with minimal human intervention.

RESULTS

Acceleration of the operations process

OBJECTIVE AND ACTIONS

They decided to implement SYNKRO in order to automate certain processes, therefore avoiding having to manually transcribe information for various systems in place.

They decided to implement SYNKRO in order to automate certain processes, therefore avoiding having to manually transcribe information for various systems in place.

TOOLS AND TECHNIQUES

Acceleration of the operations process

Increased quality of work

Increased efficiency

The SYNKRO solution now sits at the centre of these applications and relays information to the right systems. These bridges have completely changed the operator’s reality who previously had to go back and forth between different applications for the same information.

Merkur

DISCOVER OUR PROJECTS

Standardizing Production Through Digital Transformation

Manufacturing

Our client, Canam Group, specializes in the design and manufacture of metal components for the construction industry in North America. With the acquisition of three plants, Canam Group wanted to find a solution to remotely monitor the status of its machinery in order to implement production improvements.

Matritech: A Large-Scale 4.0 Turnaround

Manufacturing

Matritech is a manufacturer of metal components with varying production volumes. Operating as a one-stop shop, the company brings together multiple manufacturing processes. Merkur is supporting Matritech’s team through its major Industry 4.0 transformation.

A successful digital transition for Metalus’s new smart factory

Manufacturing

Metalus specializes in sheet metal fabrication. The company, which has seen steady growth since 1988, found itself at an impasse created by a logistics problem: its 125 employees were having to manually distribute more than 1000 work orders a week.