Numerical Simulation for the Company Pro Pac Industries

- Client

- Pro Pac Indsutries

- Sector

- Manufacturing

- Expertise

- Numerical Simulation and Physical Testing

- Product optimization

CONTEXT

CHALLENGES

ASSIGNMENT

Our numerical simulation experts, in collaboration with Pro Pac Industries, established load cases that accurately represent the forces experienced by the delimber head

They then carried out a comparative structural analysis of two versions. Following this analysis, the structure of the new Delimber Head was optimized to reduce stress on weak points and improve performance based on the criteria established by the Pro Pac Industries team.

RESULTS

Reduction in product development costs.

OBJECTIVE AND ACTIONS

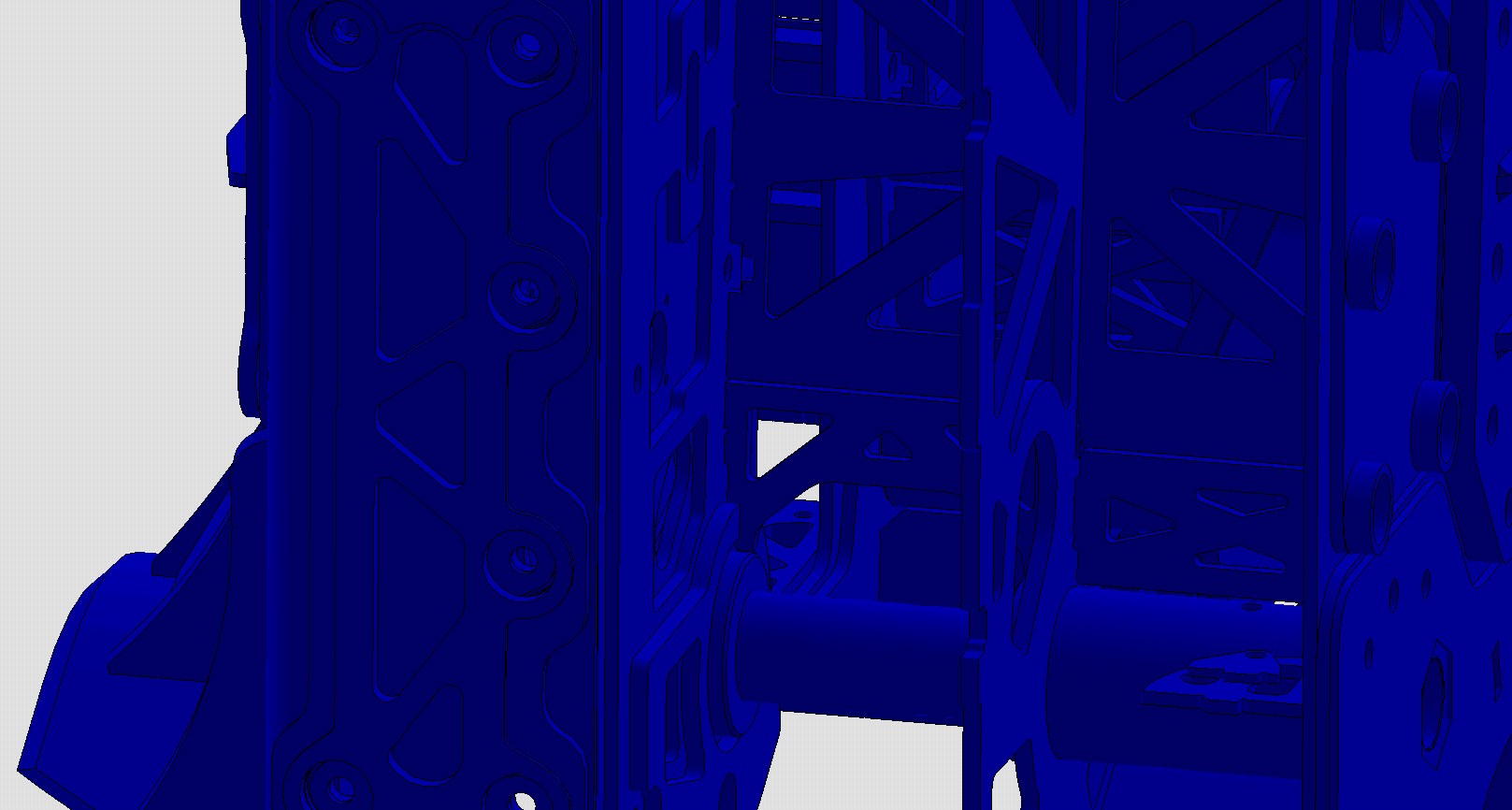

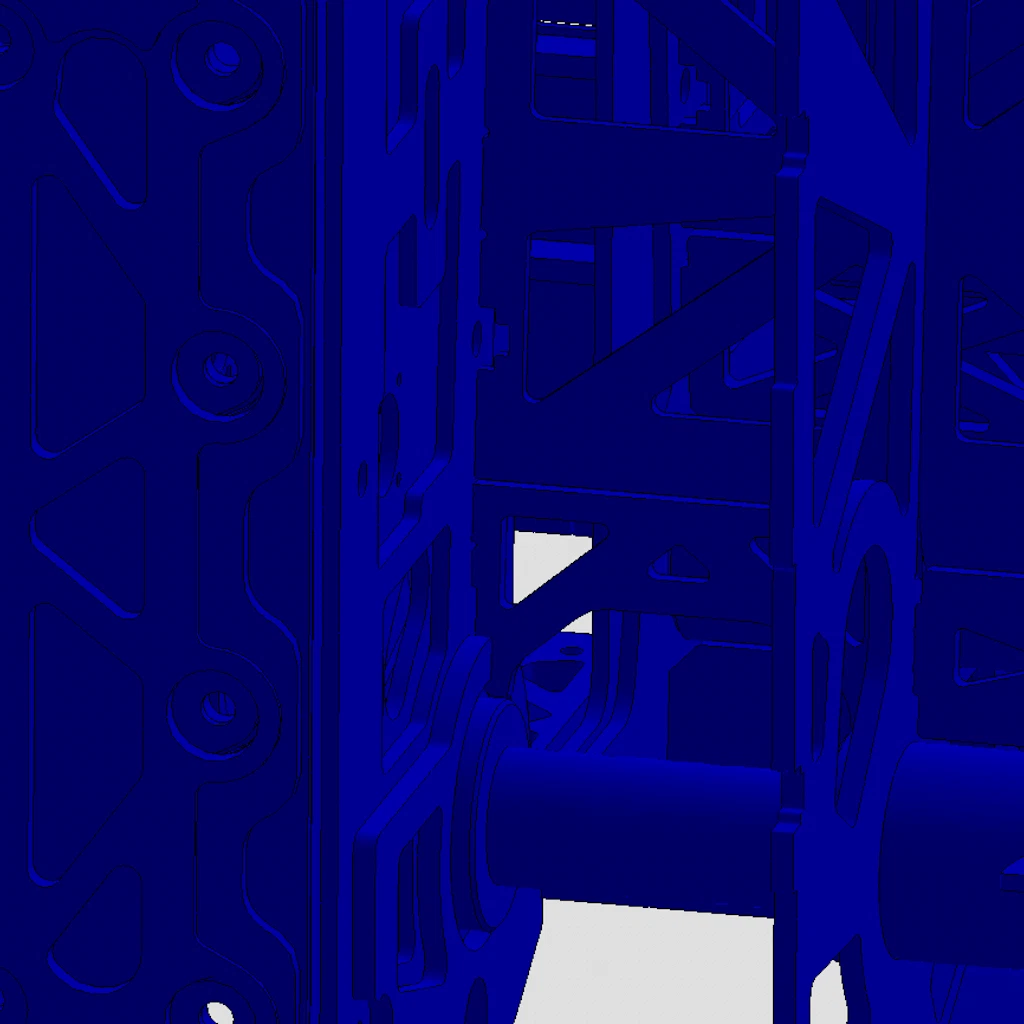

Finite Element Analysis of a Delimber Head under Static Loads

Finite Element Analysis of a Delimber Head under Static Loads

TOOLS AND TECHNIQUES

Analysis of load cases that best represent the use and failure scenarios of the existing delimber head components.

Finite element analysis of the new delimber head

Improvements in head design and material selection

DISCOVER OUR PROJECTS

Support for pontoon boat design and manufacturing

Manufacturing

Our customer needed to design and manufacture a pontoon boat for a sister company in the U.S. on their own premises, while retaining the company’s DNA. Our customer lacked engineering and project management capabilities.

Accelerating the Production Launch of a Oneka Desalination Buoy

Marine

Oneka Technologies is a startup dedicated to transforming the oceans into a sustainable and affordable source of fresh water. Oneka sought to integrate several supply chain and product development experts into its team to help plan manufacturing through its supplier network and bring the buoy into production.

Design and simulation for the passenger seats of the Long Island Rail Road In New-York

Transportation

Developed for daily commuters on New York’s suburban rail lines, the M9 seats were manufactured by our client, Khrome PT, on behalf of Kawasaki. The twofold objective was to meet strict transportation safety standards while also complying with the railcar manufacturer’s technical specifications—all within the established budget.