Design and simulation for the passenger seats of the Long Island Rail Road In New-York

- Client

- Khrome Products-Transport

- Sector

- Transportation

- Expertise

- Product Development

- Numerical Simulation and Physical Testing

CONTEXT

CHALLENGES

ASSIGNMENT

Kawasaki entrusted the development and manufacturing of the new seats (M9) to our customer Khrome Products Transport (KPT).

In this traditional and highly regulated sector, the weight of the seats had to be reduced by 25% without increasing production costs. Merkur was therefore entrusted with the design, the numerical simulation tests as well as the tests and validations in order to respect the specifications, the standards and safety constraints imposed by the transport authorities (APTA*) as well as the budgets set by Kawasaki.

*APTA : American Public Transportation Association.

RESULTS

Compliance with safety standards and design criteria (APTA)

OBJECTIVE AND ACTIONS

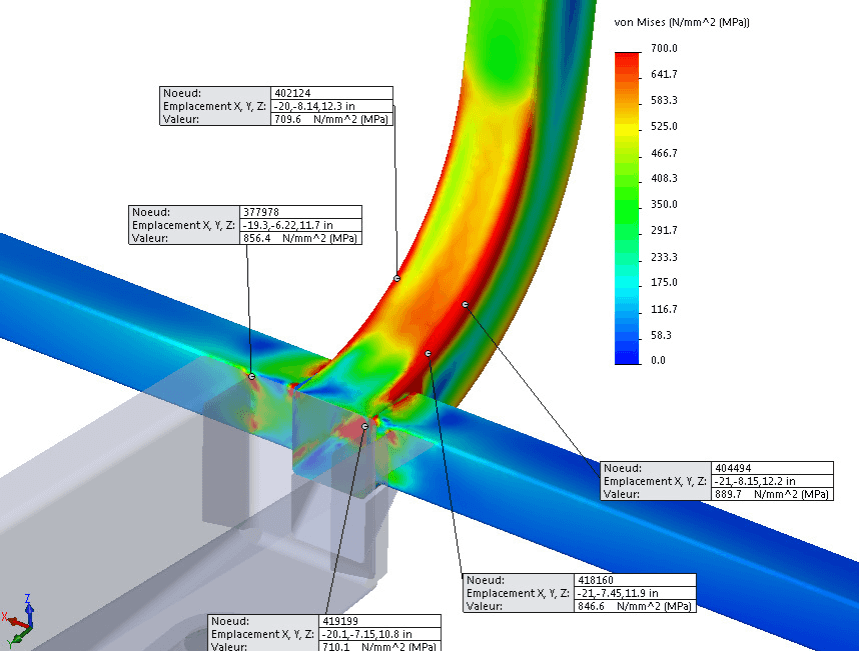

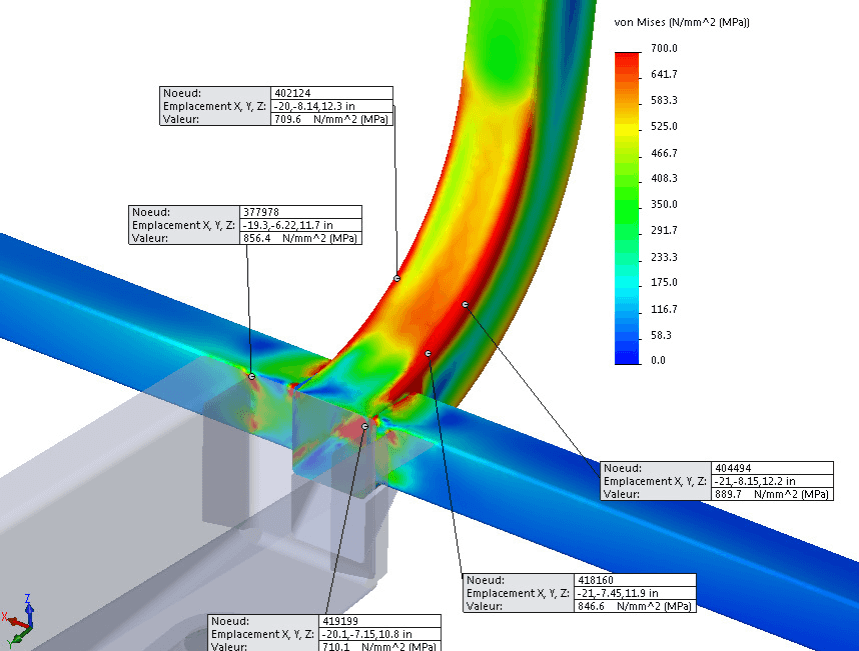

The numerical simulation carried out beforehand made it possible to reduce the number of physical tests, which in itself represents a cost saving. Indeed, in this context, the numerical simulation quickly identified the stress concentration zones of the seats due to the different load cases. Beyond comfort, finish and resistance to vandalism, the recommendations made had an impact on the weight of the seats and their durability.

TOOLS AND TECHNIQUES

Numerical simulation

Complete product development expertise

Methodology

Prototype

Testing conducted by a research and testing center, supervised by our engineers.

The M9 seats of the LIRR train are currently integrated in cars in service that are equipped with 41 seats each: they meet the current requirements of passenger car interiors where design and comfort prevail.

Merkur

DISCOVER OUR PROJECTS

Accelerating the Production Launch of a Oneka Desalination Buoy

Marine

Oneka Technologies is a startup dedicated to transforming the oceans into a sustainable and affordable source of fresh water. Oneka sought to integrate several supply chain and product development experts into its team to help plan manufacturing through its supplier network and bring the buoy into production.

Optimization of Bus Handling Equipment

Transportation

One of our customers, a manufacturer of passenger buses and motor homes, decided to replace the ferries in its passenger bus assembly plant.

Integration of an Electronic Module for Motorized Watercraft

Electrification

Merkur worked with one of its customers, a manufacturer of motorized watercraft and recreational vehicles, to modernize one of its pieces of equipment.