01 /03

We quickly clarify your current situation to identify bottlenecks, waste, and the most promising improvement levers.

- Clarify objectives

- Facilitate on-site workshops

- Map key processes

- Analyze the value chain

- Prioritize high-impact actions

02 /03

We define the target operating model and improvement levers, then build with you a coherent, realistic transformation path. Each solution is tailored to your realities to ensure lasting results.

- Define the target operating model

- Identify improvement levers

- Evaluate realistic scenarios

- Build the roadmap

03 /03

We turn the vision into concrete actions through a progressive, controlled implementation. We secure the changes and embed standards to deliver sustainable gains.

- Deploy the roadmap

- Establish governance

- Track key indicators

- Launch pilot projects

- Ensure knowledge transfer

- Support change management

Our services at the core of the integrated solution

Strategically designed, our services ensure smooth, cohesive, and high-performance management of your industrial projects. Our integrated solution reduces risks, accelerates execution, and maximizes results at every stage.

Manufacturing Strategy and Plant Layout

From diagnosis to ramp up: network design, layout, capacity and equipment selection for sustainable gains.

Operational diagnostic

A field led operational diagnostic revealing waste, bottlenecks and opportunities. Concrete, ROI prioritized recommendations to improve performance sustainably.

Lean Manufacturing

A Lean program tailored to your plant: on site diagnostic, collaborative workshops and a prioritized action plan to remove waste, stabilize processes and lift performance for the long run.

Strategic Advisory and Coaching

Strategy for manufacturers, done on the shop floor: objective diagnosis, prioritized roadmap and governed execution (PMO, KPIs, change management).

PROJECTS

Industrial plant expansion project at LPM

Manufacturing

LPM is a company specialized in closed die-forging, stamped part production and production line integration. LPM had a potential for growth and investment in more efficient machines that no longer corresponded to the structure and space of the current building.

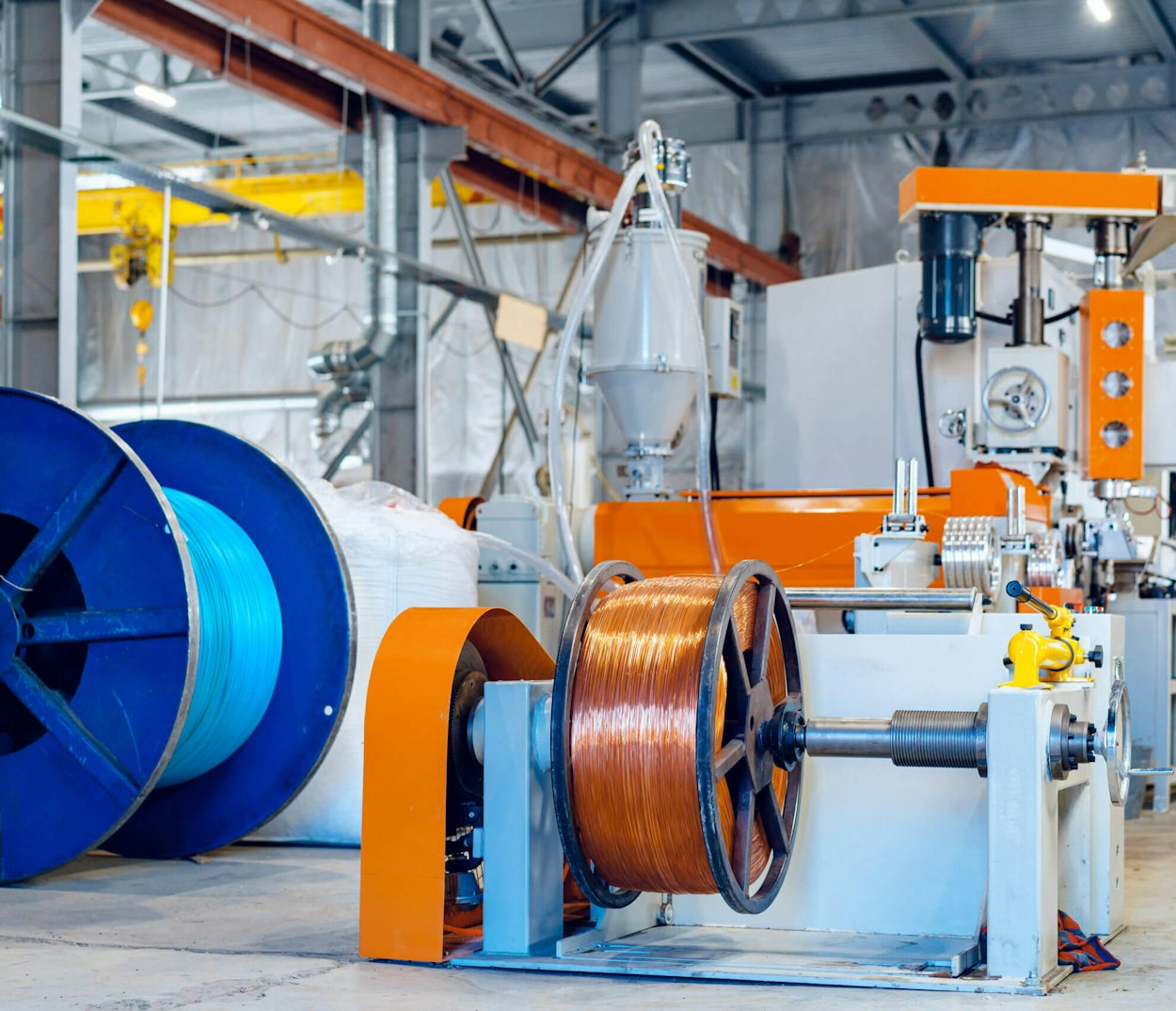

Pull Flow Adoption to Streamline Production and Reduce Work in Progress

Manufacturing

Specializing in the manufacturing of electrical cables coated with high-performance materials, our client operated under a push flow production model, based on make-to-stock manufacturing. The company initiated a shift to a pull flow system to reduce work-in-progress, streamline flows, and increase organizational agility. Merkur took over and successfully implemented this transformation.

ARTICLES

Control and reduce your Manufacturing Costs with Lean

How can you increase productivity, shorten production lead times, lower inventory, and cut more than 50% of manufacturing errors and defects?

How your Employees Contribute to the Success of an Operational Excellence Mandate with Merkur

Operational excellence is an essential strategic lever for companies seeking continuous improvement. Regardless of the technical complexity of mandates, their success depends above all on the active involvement of employees at every stage.

The Winning Combination of Operational Excellence and Intelligent Factory

The combination of operational excellence and smart factory can help companies improve their competitiveness in a constantly changing market.