Lean Manufacturing

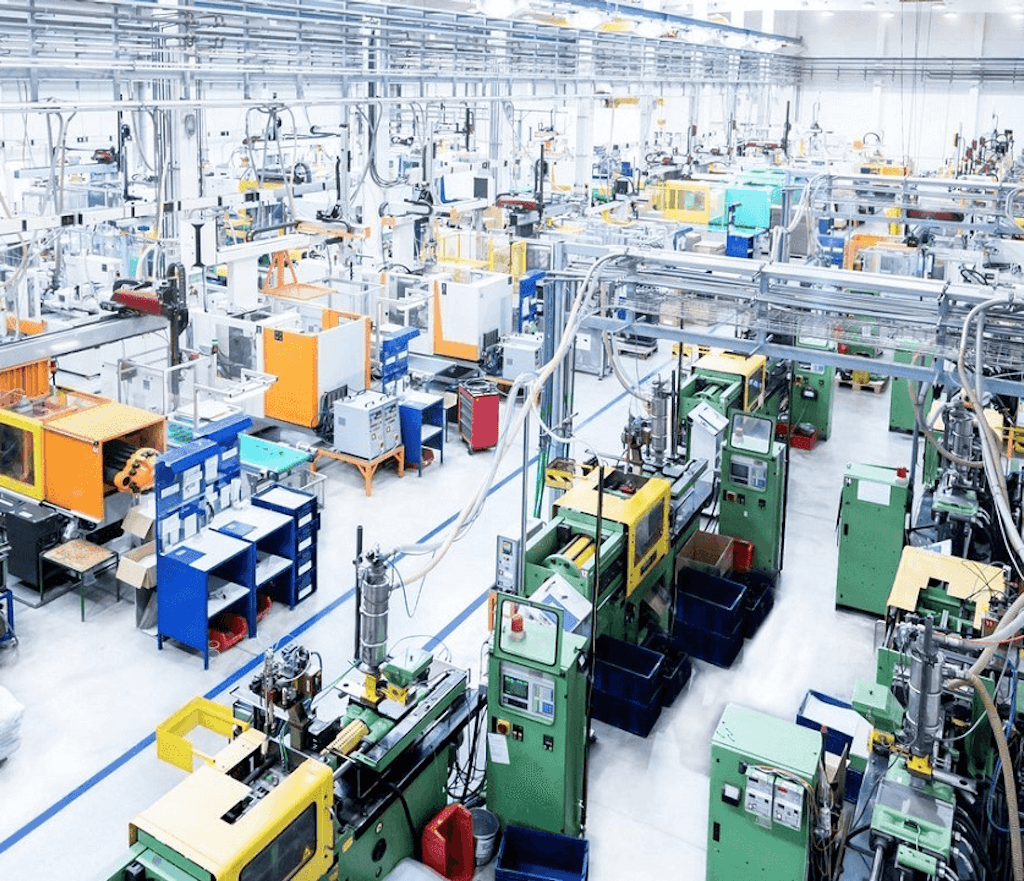

Optimize your operations with a Lean approach tailored to your plant’s reality. Our experts turn everyday obstacles into performance levers and lasting results.

OUR EXPERTISE

A continuous improvement culture built together

A continuous improvement culture built together

We support manufacturing companies in implementing Lean strategies that improve efficiency, reduce waste, and strengthen team engagement. Our approach is based on rigorous on-site diagnostics, participative workshops, and a lasting transfer of skills to your teams.

Whether the goal is to stabilize your processes, optimize your flows, or increase flexibility, our experts help you build a continuous improvement culture tailored to your reality. With proven tools and a people-first approach, we deliver concrete, measurable, and sustainable results.

- Map you value stream (VSM)

- Implement Lean work cells

- Optimize changeover times (SMED)

- Reduce waste (Muda, Muri, Mura)

- Make employees’ work easier through visual management

- Deploy a 5S culture

- Train and coach your teams on Lean practices

- Analyze problems and pain points (PDCA, A3)

Tools

Value Stream Mapping (VSM)

Gemba walks & on-site observations

Spaghetti diagrams / time and movement analysis

OEE/TEEP analysis (overall equipment effectiveness)

Ishikawa (fishbone), Pareto, 5 Whys

Lean / Industry 4.0 maturity audit

Performance measurement and key indicators (KPIs)

Process mapping (SIPOC)

Capacity and bottleneck assessment

Workstation ergonomics (ISO, CNESST, CSA standards)

Adopt a structured approach to build a lasting continuous improvement culture focused on your real challenges. Together with your teams, we lay strong foundations that transform your operations for the long term.

Lean applied to your industry

Our solutions are tailored to your flows, your teams, and your real constraints to maximize operational efficiency.

Lean and multi-sector experts

Our Lean Six Sigma–certified specialists work closely with your production teams to deploy industry best practices.

Concrete results that last

We build solid foundations to deliver measurable gains, embed continuous improvement, and support long-term performance.

PROJECTS

New Production Strategy for La Marguerite & Co.

Agri-Food

La Marguerite & Co. offers catering and take-out services for corporate events. Its success has brought new challenges for the pastry team in meeting rapidly growing demand. Rethinking the production strategy is essential to address the industry’s real constraints and support growth, particularly within large-scale retail distribution.

Masonite doubles its factory production capacity and reduces delivery time by 30%

Manufacturing

Lemieux Doors (now the property of Masonite) specializes in the manufacture of wooden doors. After many years of strong growth, the company found itself dealing with a new industry trend: customization.

ARTICLES

Control and reduce your Manufacturing Costs with Lean

How can you increase productivity, shorten production lead times, lower inventory, and cut more than 50% of manufacturing errors and defects?

How your Employees Contribute to the Success of an Operational Excellence Mandate with Merkur

Operational excellence is an essential strategic lever for companies seeking continuous improvement. Regardless of the technical complexity of mandates, their success depends above all on the active involvement of employees at every stage.

The Winning Combination of Operational Excellence and Intelligent Factory

The combination of operational excellence and smart factory can help companies improve their competitiveness in a constantly changing market.