Operational diagnostic

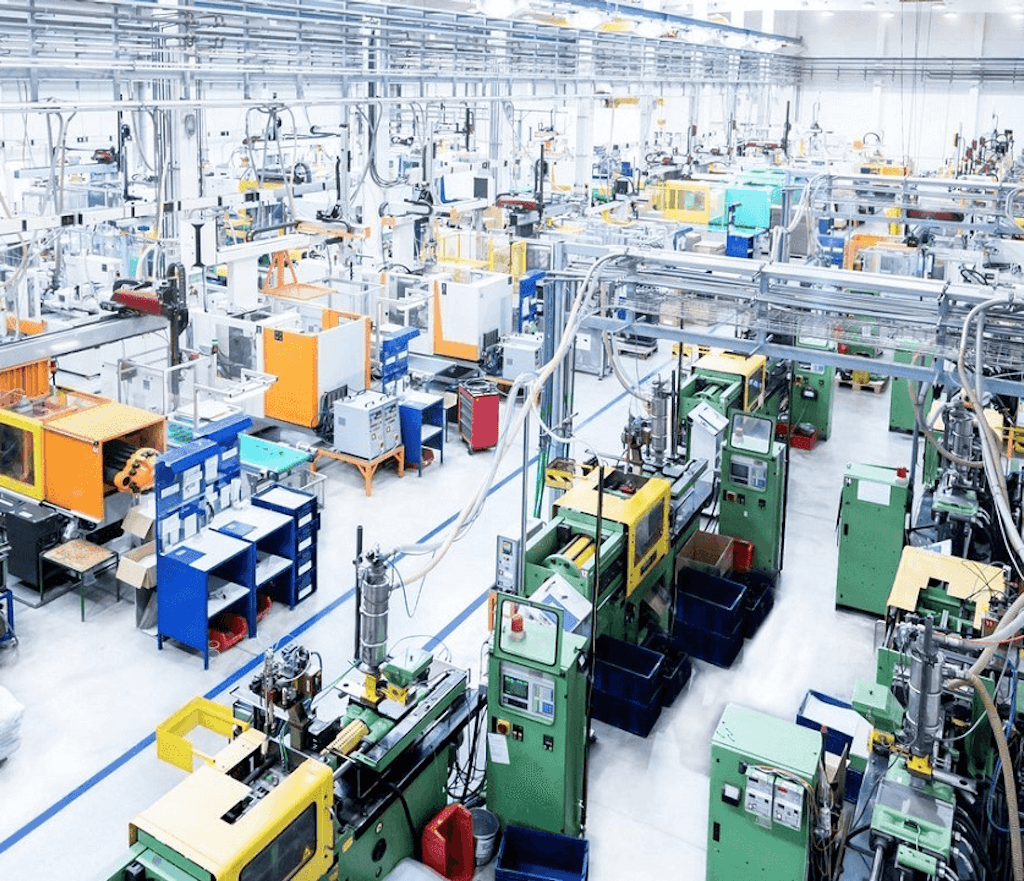

Our experts analyze your operations to identify inefficiencies, pinpoint priorities, and turn findings into concrete actions that deliver lasting performance improvements.

OUR EXPERTISE

An objective, results-driven assessment

An objective, results-driven assessment

At Merkur, we work directly on the shop floor to conduct a comprehensive diagnostic based on concrete, measurable data. We analyze your production processes, logistics flows, digital tools, organizational structure, and management methods to identify the most impactful performance levers.

Our recommendations are objective, prioritized by potential gains, and immediately actionable. Through a collaborative, fact-based approach, we build team buy-in and accelerate solution implementation.

Make informed strategic decisions, reduce operating costs, and sustainably improve your manufacturing efficiency.

- Map your processes and value streams

- Identify waste and operational pain points

- Assess the performance of your teams, equipment, and systems

- Get a clear, prioritized, ROI-focused action plan

- Benchmark your practices against industry best standards

- Prepare for automation and digital transformation projects

- Benefit from an external, objective, solution-oriented perspective

Tools

Value Stream Mapping (VSM)

Gemba walks & on-site observations

Spaghetti diagrams / motion and travel analysis

OEE/TEEP analysis (overall equipment effectiveness)

Ishikawa (fishbone), Pareto, 5 Whys

Lean Management

Performance measurement and key indicators (KPIs)

Process mapping (SIPOC)

Capacity and bottleneck assessment (line balancing)

Workstation ergonomics (ISO, CNESST, CSA standards)

An external perspective to quickly identify on-the-ground pain points, structure your priorities, and guide your decisions. Clear findings and practical recommendations, delivered rigorously and straight to the point.

An objective external view of your operations

Grâce à nos diagnostics rapides et structurés, nous mettons en lumière les sources de gaspillage, les points de blocage et les opportunités d’amélioration souvent invisibles de l’intérieur.

Multi-sector and international experience

Our engineers rely on industry best practices to provide an impartial, practical, no-compromise assessment of your operations.

A detailed, precise report

Our team delivers a clear, prioritized diagnostic that showcases tangible, measurable improvement opportunities that can be applied directly on the shop floor.

PROJECTS

Industrial plant expansion project at LPM

Manufacturing

LPM is a company specialized in closed die-forging, stamped part production and production line integration. LPM had a potential for growth and investment in more efficient machines that no longer corresponded to the structure and space of the current building.

Warehouse Consolidation and Design of a Multisite Logistics Network

Manufacturing

Our client in the powersports industry aimed to introduce a new range of modular products and double its production.

ARTICLES

Control and reduce your Manufacturing Costs with Lean

How can you increase productivity, shorten production lead times, lower inventory, and cut more than 50% of manufacturing errors and defects?

How your Employees Contribute to the Success of an Operational Excellence Mandate with Merkur

Operational excellence is an essential strategic lever for companies seeking continuous improvement. Regardless of the technical complexity of mandates, their success depends above all on the active involvement of employees at every stage.

The Winning Combination of Operational Excellence and Intelligent Factory

The combination of operational excellence and smart factory can help companies improve their competitiveness in a constantly changing market.