Mechanical engineering and design

From product architecture to technical validation, we combine rigor and creativity to turn your ideas into high-performance, reliable products ready for manufacturing.

OUR EXPERTISE

Design better, validate faster, industrialize with confidence.

Design better, validate faster, industrialize with confidence.

Design high-performance, reliable, and manufacturable products with our expertise in mechanical engineering and design. We support you at every stage of development—from product architecture to technical validation—through detailed design, simulation, and optimization.

Our approach combines engineering rigor, creative design thinking, and a strong command of manufacturing requirements. By integrating usage, cost, and production constraints from the outset, we reduce risks, speed up time to market, and maximize delivered value. Work with a team fully committed to the technical and commercial success of your products.

- Define the product’s mechanical architecture

- Select materials, processes, and components

- Create 3D models and generate technical deliverables

- Optimize design for cost and manufacturability

- Simulate performance

- Analyze technical risks

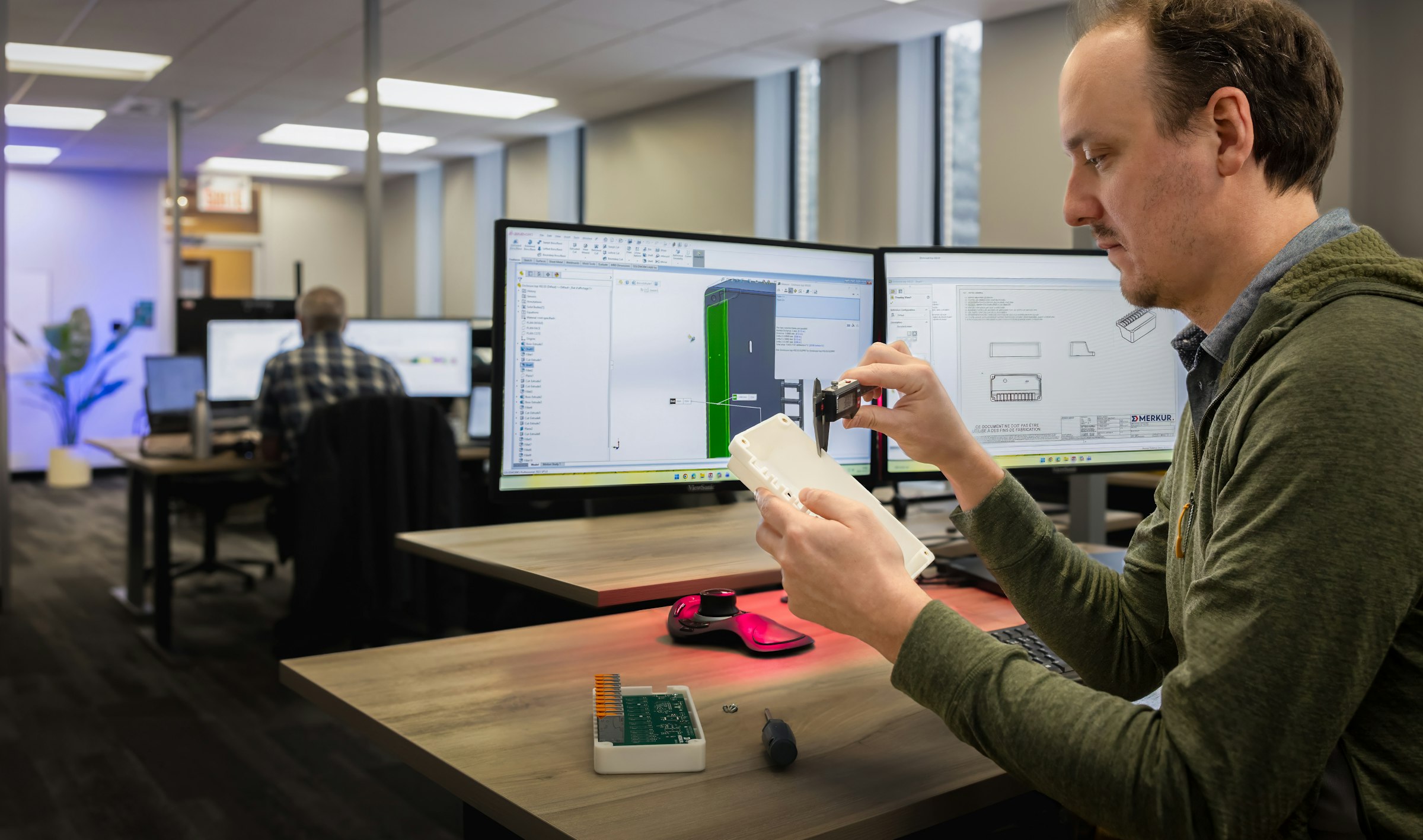

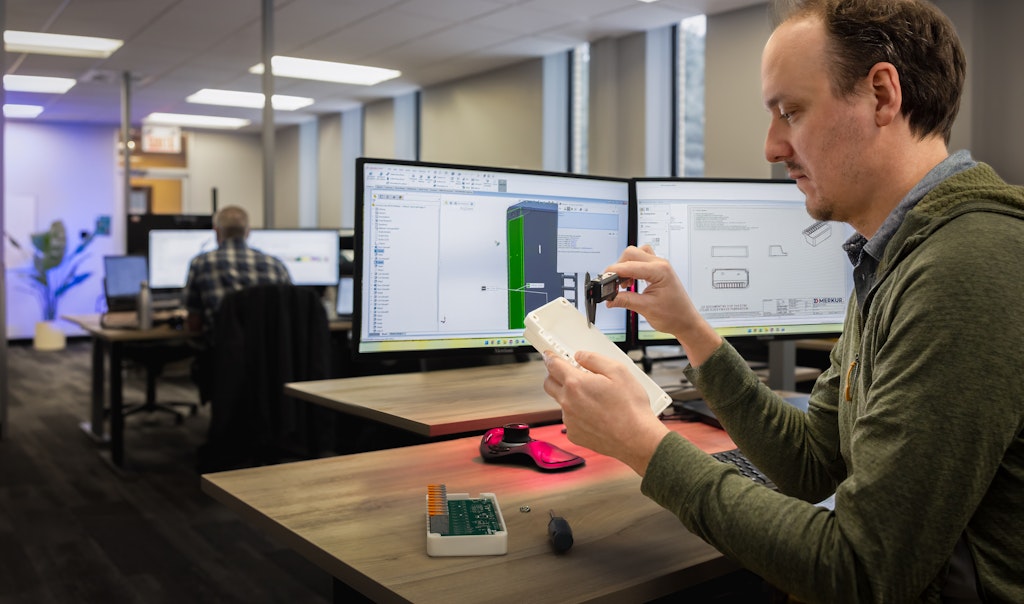

- Validate the design through testing and prototyping

- Prepare industrialization in coordination with production

Tools

Catia V5/V6, 3DEXPERIENCE, SolidWorks, NX, Solid Edge, Inventor, Fusion 360, and PTC Creo

FEA analysis (Ansys, Abaqus, SW Simulation)

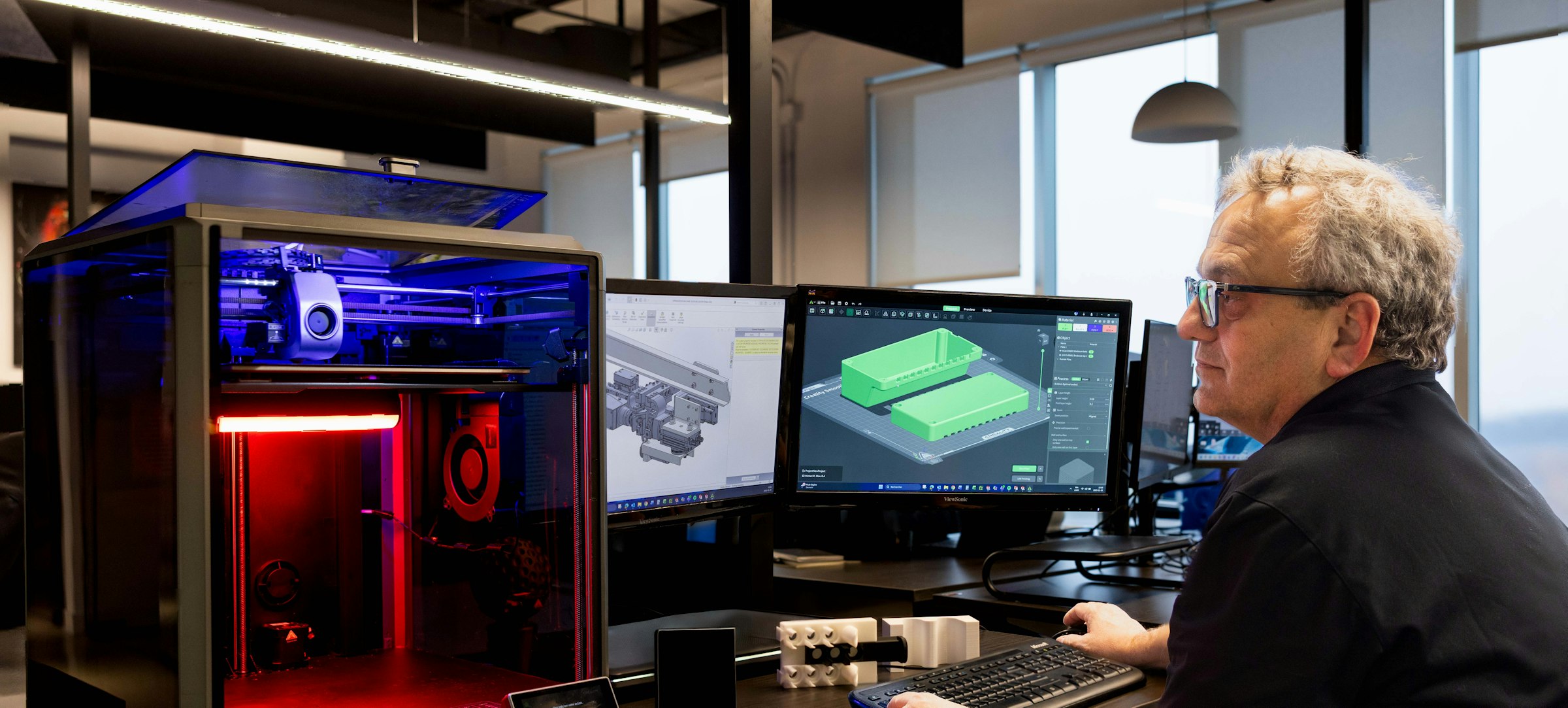

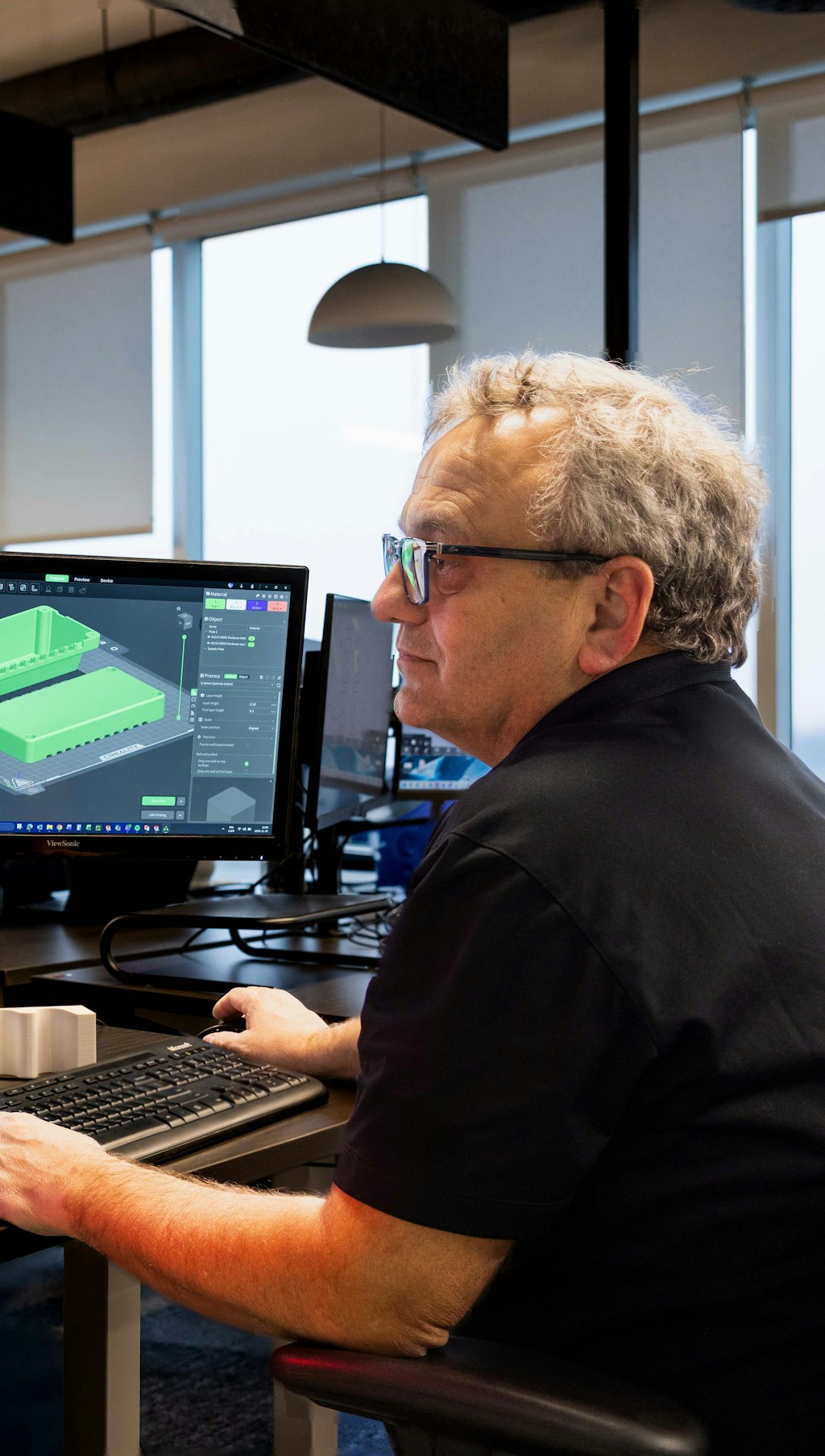

3D printing and rapid prototyping

Integration of new technologies

FMEA

DFx (DFMA, DTC, DTQ, etc.)

Combine performance and innovation to create reliable, manufacturable products through our expertise and integrated mechanical design approach.

Mechanical architecture and optimal design

Turn your functional and regulatory requirements into a robust, modular, manufacturable concept, ready for validation and production.

Our team at the heart of engineering

Our designers and engineers model, analyze, and validate every component to ensure reliability, precision, and cost control.

A complete approach to industrializing your products

Combine simulations, testing, and prototyping to speed up validation, reduce risks, and ensure a successful production launch.

PROJECTS

Engineering and design of a new armored truck in collaboration with the Cambli team

Defense and Security

The team at Cambli, the largest armored truck manufacturer in North America, wanted to diversify their product line to remain competitive and achieve their goals. They called on Merkur’s experts to accelerate the design of a multi-functional window vehicle adapted to extreme conditions in less than 6 months.

Design and simulation for the passenger seats of the Long Island Rail Road In New-York

Transportation

Developed for daily commuters on New York’s suburban rail lines, the M9 seats were manufactured by our client, Khrome PT, on behalf of Kawasaki. The twofold objective was to meet strict transportation safety standards while also complying with the railcar manufacturer’s technical specifications—all within the established budget.

ARTICLES

Generative Design: Merging Human Intuition and Artificial Intelligence

In product development, some innovations take time to catch on—until they become simple enough to transform everyday practices. That’s exactly what’s happening with generative design, an AI-powered approach that helps design faster, lighter, and smarter by focusing solely on what matters.

Knowing your Market and your Customers: The Key to Successful Product Development!

Do you see opportunities for innovation and improvement that could benefit your company? Do you have a project in mind that you’d like to present? Make the most of the summer to get ready!

Simultaneous Engineering and DFMA Integration: Crucial Elements in the Product Development Process

In the complex world of product design, certain approaches stand out, such as DFMA (Design for Manufacturing and Assembly), which enables products to be designed in such a way as to make them easier and less costly to produce and assemble. When integrated with simultaneous engineering, DFMA brings many advantages, which we will explore in this article.